Efficiency and productivity are crucial to maximizing profits in the fast-growing manufacturing world. Industries are working under pressure to minimize waste, boost velocity, and improve product and service quality at affordable costs. Based on the Toyota production system, Toyota’s lean management simulation games provide the best way to achieve these goals. However, many companies struggle to teach lean concepts in a way that brings true behavioral transformation. Traditional training methods like classroom lectures and slide presentations cannot encourage real improvement. GET LEAN simulation games change this situation by providing an interactive and hands-on experience. The game takes 25 years for development before hitting the market, and the simulation enables the team to learn these things practically.

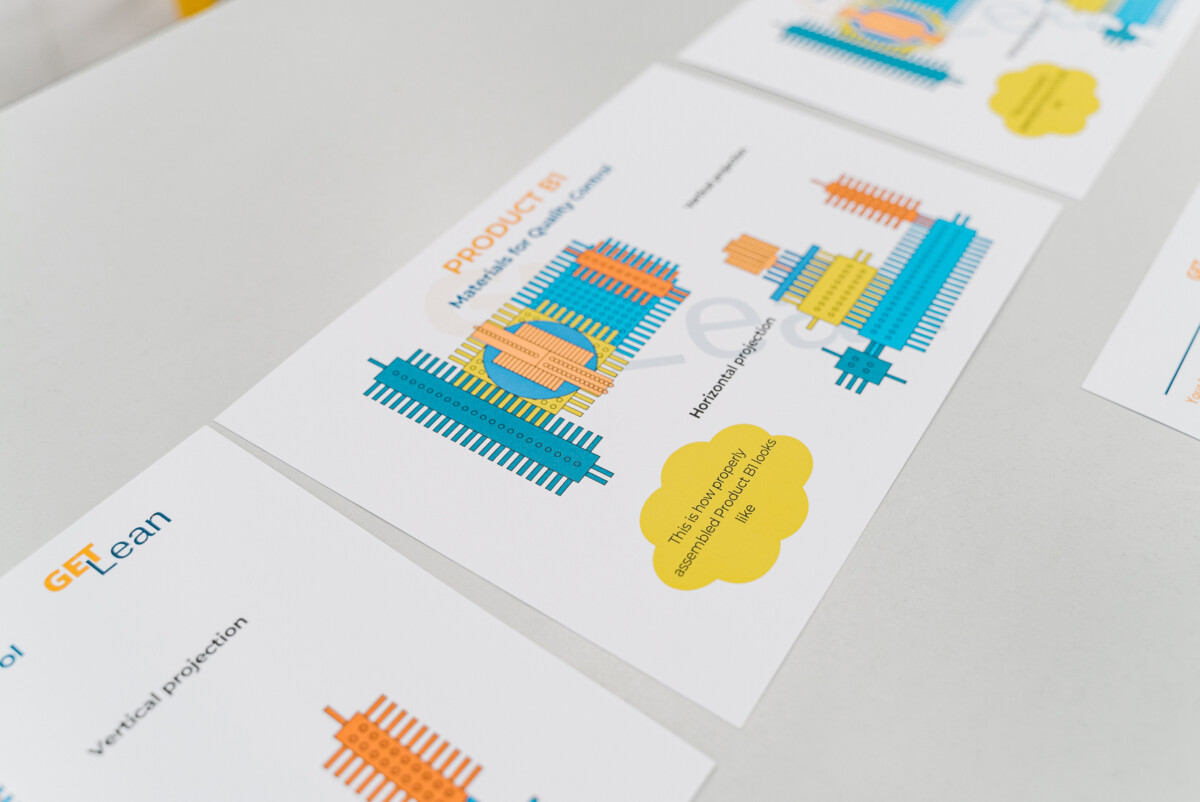

Example materials from lean management games—technological cards that depict the desired production workflow, supporting interactive training and process optimization.

What Is Lean Management and Why Does It Matter?

Lean management is not just a way but a mindset that focuses on making more results with fewer resources, embodying various lean concepts. Before explaining how the GET LEAN simulation game works, it is essential to understand what lean means, including concepts like takt time, kanban, and one-piece flow, and why it matters today.

Defining Lean Management

Lean management simulation games are used to identify and eliminate things that do not bring value to customers. We value minor, continuous improvements that combine our commitment to quality and respect for people. Lean companies focus on efficiency, delays, and what is truly important. The result is a culture where everyone pursues a better way of working daily, emphasizing the importance of pull in the production process.

Key Benefits for Organizations

Lean allows businesses to save costs, increase quality, and minimize delivery time. The team will be taught how to recognize and eliminate waste of material, time, or effort. This will make production faster, decrease errors, and enhance customer satisfaction and relationships. These results accumulate over time, reinforcing the continuous improvement cycle, leading to higher profit margins and increased resistance to supply chain disruptions and human resources shortages.

The Role of Employees

Lean will not succeed without employee cooperation. Therefore, the lean strategy emphasizes participation at all levels and provides clear instructions to all team members. Employees closest to the process have the best ideas for improvement. The whole system is improved when they are empowered to try out ideas and implement changes. This participation makes achievement easier and makes lean part of daily work, not just a program.

The Gap in Traditional Methods

Traditional lean training explains “what to do,” but does not explain “how to do it.” Even workshops describing tools give you little chance to try the tools under pressure. Without hands-on practice, the theory remains abstract. Simulations fill this gap because learners can play roles, make decisions, and check the effects of lean tools in context. This real-time test enhances understanding and commitment over lectures.

The Power of Simulation-Based Training

Traditional lean training often involves teams and encourages real change. So, simulation-based learning, including implementing a short game, stands out. Through hands-on experience, real-time feedback, and teamwork, we make lean game concepts meaningful and real by incorporating various features that enhance learning.

Real-World Learning in a Safe Space

Lean technology can be practiced without stopping actual operations in simulation games. During the game, participants take roles in a work cell, follow the process, manage the materials, and sometimes utilize paper for testing layouts. Mistakes do not compromise actual customers or funds but are an opportunity to learn. By testing changes in a controlled environment, teams build confidence in applying lean tools at work.

Active Learning vs. Passive Learning

Passive learning methods like lectures sometimes feel separated from daily tasks. Simulation-based training, on the other hand, is active and practical. Participants think, plan, execute, and look back. Make real-time decisions and adapt strategies instantly. Such involvement fosters problem-solving skills so that lean game concepts can accommodate variation and be established.

Real-Time Feedback and Teamwork

GET LEAN games provide immediate feedback to your team. Participants can see how changes affect orders, costs, and one-piece flow. The team will discuss the results, analyze the root causes, and plan improvements. This cycle of action and reflection reflects actual lean game practices, including several rounds of kaizen, which can lead to many improvements over time. The important thing is that this cycle builds cooperative relationships beyond functional roles and standard work practices, which can demonstrate the team’s responsibility, particularly in Lean Six Sigma initiatives.

Improved Retention and Support

Research has shown that people better remember what they did than what they heard or read. The team can test their ideas in the simulation and see the results directly. As a result, employees understand the lean tool and support its use. This support is crucial. If you know the tool and believe in its effective lean games, you can continue to use it for a long time after the workshop to demonstrate its benefits.

Deep Dive: How the GET LEAN Simulation Game Works

GET LEAN Simulation. To truly understand a game’s value, it is helpful to understand the detailed instructions on how to operate it effectively. This section describes the structure, team configuration, and lean tools teams use during simulation as one set for effective learning.

Team Organization and Roles

The Lean simulation game is designed for teams of 13 to 16 people. Each player is responsible for one of the eight stations: acceptance, work cell, lean manufacturing games, and quality control. This configuration reproduces the actual factory and service environment.

Participants will experience practical decisions that affect process flow. This visualization enables us to understand the relationship between roles and the primary goals we aim for.

The game proceeds with six timed sessions. Each session includes production execution, performance review, and kaizen planning segments. The team decides on an improvement for the next four rounds. As the session progresses, the team can practice lean game methods (small lot production, route change, process adjustment, etc.). After that, we will compare the set goals and adjust the strategy as needed.

Business Goals and Accountability

The team is not just playing, but aiming to achieve the goal. They track indicators such as order completion rate, backlog, lead time, and cost per unit. If you fail to achieve your goals, discuss the reasons, plan changes, and demonstrate how different strategies can lead to success. This approach fosters a sense of responsibility and promotes critical thinking to push for better results. Teams are urged to consider tradeoffs and focus on system efficiency rather than task speed.

Core Lean Principles in Action

In the GET LEAN game, participants learn the core of lean thought through practice. They reduce batch size, improve flow, reduce waiting time by single processing, and organize the workspace by 5S. Students build a simple pull system using Kanban to simplify the process and adjust the layout. These improvements help teams understand the link between lean six-sigma thinking and actual outcomes (e.g., shortening cycle times or reducing errors).

Key Benefits of the GET LEAN Simulation Game

GET LEAN simulation games make understanding and applying lean game principles easier through practical practice and theory. The key benefits that organizations and teams experience using this attractive training tool, which includes LEGO bricks for creative learning and engaging lean management games, particularly in software development contexts, are:

Practical, Role-Based Learning

In these field training sessions, participants must assume the actual role and choose from various options for operating a workstation. They quickly learn that small changes make a big difference in quality, cost, and flow.

This approach enables participants to internalize lean tools through active engagement and play, enabling meaningful learning over classroom theoretical learning. At the same time, practical games develop confidence and preparation to apply Lean Six Sigma methods at work.

Building Cross-Functional Cooperation

Simulation facilitates communication and collaboration by gathering participants from various company departments. Team members learn how one role affects another and how to support one another for common success. This team-based learning creates stronger relationships, better planning, and better problem-solving skills, all essential for actual lean deployment.

You can use the GET LEAN kit as many times as you want. Facilitators can adjust complexity from beginner to expert level depending on their team’s experience. You can also customize your games to fit your group size and industry.

The kit contains all the necessary materials, guides, templates, a table setup diagram, etc., and does not require external assistance. This flexibility makes the game a valuable long-term resource, especially when fun elements like LEGO bricks are incorporated into the training.

Designed by a Lean Expert

This simulation is not just a theory. Based on 25 years of lean deployment experience in factories and offices, the game comes with detailed presentation materials and facilitator guides that reflect real-life insights. You can progress the game even if you don’t have lean games and simulation training. Because of the built-in instruction, trainers and internal lean Lego game promoters have adopted approaches that are easier to share.

Inclusive for Everyone

The game is simple enough to understand even the team members in the field, but provides deeper learning for supervisors and engineers. Regardless of the role, everyone can discover how the lean tool works. This inclusivity helps make Lean Six Sigma feel like part of everyday work rather than a separate program. Lean is a shared mindset when employees join across hierarchies.

What’s Included in the GET LEAN Package

The GET LEAN games package contains all the necessary materials, including LEGO bricks, for practical lean games training:

- Physical Materials: Setup guide, table placement diagram, marker, stopwatch, tape, pen, ensuring inclusion of software development contexts.

- Digital Materials: PowerPoint slides, cost analysis sheets, warehouse specifications, and order lists that explain lean theory and gaming procedures.

- Training Support: A comprehensive facilitator guide with detailed presenter notes for each slide. It explains specifically what a trainer should say in each simulation phase.

Bonus: Free Access to Lean Training Courses

In addition to practical simulations, when you purchase a GET LEAN simulation game, you will receive a valuable bonus of free access to lean games training sessions and courses by experts, including insights on software development, which will deepen your team’s knowledge and help you improve continuously.

Get Additional Learning at No Cost

When you purchase the GET LEAN kit, you receive a free access code to SabatConsulting’s online green course. This bonus helps trainers and participants improve their skills by learning lean games and simulation principles, tools, and case studies based on simulation. In the course, teams can learn theories at their own pace and play to strengthen their game lessons.

How the Access Code Works

After purchase, the access code will be sent by email. Share this code with your team members and trainers to unlock your course on the SabatConsulting portal. The course includes video, readings, quizzes, and case studies to complement the simulation. Learners can move independently and focus on the most relevant tools.

Aligning Simulation with Theory

By combining practical simulations with structured online lean courses, learners get a balanced lean management games experience. Games promote learning through practice. Online training provides context for lean Lego game history, tool definitions, and how to apply ideas beyond games.

This multi-layered learning model, which can be divided into four rounds, builds a deep understanding and helps maintain lean game improvement in the workplace.

Why This Training Works for Everyone

Lean concepts may feel complex and disconnected from everyday tasks, but GET LEAN simulation games make them clear and practical. The following is why this training session’s approach matches the needs of organizations of all types, sizes, and levels of experience.

Making Lean Simple and Relatable

Lean may initially feel abstract, but the simulation breaks it into realistic and manageable steps. Teams can realize how process improvement reduces lead time and cost. Putting ideas into action, including concepts like takt time, makes it easier for participants to understand lean games and simulation in everyday tasks.

GET LEAN suits whether the team manufactures the product or processes the information. In lean manufacturing games, the station represents the actual production process. In offices and management departments, roles can take over and simulate the flow of approvals and documents.

This game is helpful for diverse learners because it adapts to different industries and operating models.

Onboarding New Team Members

Participating in the GET LEAN simulation will introduce new employees to the lean Lego game and corporate culture. Visualize the impact of various roles in interdisciplinary collaboration and decision-making on the overall outcome, aligning efforts with customer demand.

This lean manufacturing simulation game helps new team members contribute quickly and confidently to process improvement.

Working Across Departments

In lean six-sigma initiatives, simulations connect cross-functional teams. People who don’t usually work together get the opportunity to practice communication and planning. These interactions build trust, cross-sectoral awareness, and shared commitments and become essential to extensive improvement efforts.

Use Cases and Implementation Tips

GET LEAN simulation games are flexible and fit many training environments. Whether running a monthly session or launching a lean games and simulation program, here are general use cases, practical tips, and considerations for handling variation to get the best results.

Monthly Training for All Staff

Many companies conduct regular GET LEAN simulations for all employees. Monthly sessions allow you to keep your lean in mind, try new ideas, and participate in a short game, reinforcing learning. Participants learn new concepts and return to the workplace with clear improvement ideas. These minor improvements will pile up over time.

Part of Lean Certification Programs

This simulation is a valuable educational tool for lean game certification organizations. Participants will experience the lean tool in the game, reflect on the results, and apply it to an actual improvement plan. At the time of approval, it provides concrete evidence of lean understanding.

During Kaizen Weeks or Events

Kaizen Week focuses your team on quick improvements. You can incorporate the simulation first or last to set the context and verify the results. As part of the event, the team learns techniques, tests ideas, and applies discoveries directly to the process.

Trainer Tips for Maximum Effectiveness

To achieve actual results, the trainer should indicate the purpose of each round. Letting players change roles improves learning effective lean games. You can see the progress over time by checking the performance data after each session. Finally, linking the game’s results to the work will strengthen the relevance.

Why Now Is the Time to Invest in Lean Skills

In today’s rapidly changing business environment, companies face rising costs, labor shortages, and intensifying competition. Investing in lean skills is now the key for teams to work more efficiently, reduce waste, and achieve a complete competitive advantage in all industries.

Facing Rising Costs

Global raw material prices and labor costs continue to rise. For companies to remain competitive, all operations need to be streamlined. Lean games provide a proven toolkit to reduce waste, mistakes, and improper resource utilization. Simulation helps teams implement these tools quickly.

Responding to Staff Shortages

Many industries are facing labor shortages. Lean practice helps you achieve more with fewer people by simplifying tasks and improving one-piece flow. GET LEAN games provide employees with experience streamlining their processes, giving them an advantage in managing on-site lean games and simulation teams, regardless of task variation.

Dealing with Supply Chain Disruptions

Unexpected shortages and transport delays prevent production. Lean tools help teams build flexibility and reduce excess inventory. The team prepares the lean manufacturing simulation game using paper to test alternate layouts and batch sizes, ensuring informed choices are made before confusion occurs.

Lean as a Strategic Must

Lean is no longer a secondary project but the core of business strategy. Companies that adopt lean thinking early will gain efficiency, resilience, and clarity. The GET LEAN simulation trains teams to think and act lean and build a lean games culture. This focus is a solid asset for the present and the future.

Conclusion

GET LEAN simulation games provide a practical way to teach lean principles through real-world scenarios. Learning from teams across roles through practice, we help improve communication, decision-making, and process efficiency. With lifetime licenses and access to all materials granted, it is a wise investment for companies to focus on continuous improvement.

Created by a lean game expert with over 25 years of experience, this lean management simulation game training tool is readily incorporated into workshops, onboarding, or certification programs. If you are ready to improve your team’s work, an excellent way to enhance your training efforts is to

For a comprehensive look at the game’s features and benefits, please visit our lean management game description page. Remember, the simulation is available in 6 languages, making it ideal for global organizations seeking consistent, high-impact Lean training.