Power of Experiential Training

In today’s dynamic business landscape, companies must continually adapt to intensifying competition by streamlining production processes, reducing waste, and driving continuous improvement. Lean Manufacturing—rooted in the philosophies of the Toyota Production System—provides a proven framework for achieving these objectives. However, traditional training methods such as classroom lectures or slide-based presentations often fail to embed these principles tangibly. This is where lean manufacturing games come into play. These interactive simulations are usually delivered in structured training sessions, where participants actively play and engage in hands-on exercises to learn lean concepts. Using materials like plastic bricks, paper, and markers, these games offer a practical, engaging learning method that bridges the gap between theory and practice, leading to better retention, a more proactive workforce, and lasting improvements in operational performance. Add-on sets or supplementary materials can further enhance hands-on learning activities in lean manufacturing games, providing additional opportunities for participants to deepen their understanding and engagement.

This article will explore lean manufacturing games, how they work, and why they are crucial for organizations aiming to embed lean principles into their culture. We will also delve into the benefits of experiential training compared to conventional methods, the practical implications for waste reduction and process optimization, and how these games foster innovation and teamwork through practical exercises.

Understanding Lean Manufacturing and the Need for Engaging Training

The Lean Manufacturing Philosophy

Lean Manufacturing is a systematic approach focused on waste elimination, process optimization, and continuous improvement. Originating from Toyota’s production practices, lean principles include techniques such as:

- 5S (Sort, Set in order, Shine, Standardize, Sustain): Organizing and maintaining workplace efficiency.

- Kaizen (Continuous Improvement): Constantly refining processes to enhance productivity.

- Just in Time (JIT): Reducing inventory waste and ensuring efficiency.

- Kanban: Visual scheduling systems that improve workflow management.

While these methodologies effectively reduce costs and improve quality, simply understanding the theory is insufficient. Organizations need a way to translate these abstract concepts into everyday business practices.

Shortcomings of Traditional Training

Traditional training methods—often reliant on lectures, manuals, or slide presentations—can be passive and disconnected from real-world application. Common issues include:

- Low Engagement: Employees frequently become disengaged when faced with one-way information delivery.

- Poor Retention: Without hands-on application, theoretical concepts are quickly forgotten.

- Lack of Practicality: The connection between theory and daily work is often unclear, making it difficult to implement Lean practices effectively.

- Resistance to Change: Conventional methods may not address the psychological barriers, such as fear of failure, that hinder transformation.

These challenges underscore the need for more interactive, practical, and engaging approaches to learning—enter lean manufacturing games.

What Are Lean Manufacturing Games?

Lean manufacturing games are interactive simulations that transform the theoretical aspects of lean methodologies into dynamic, practical experiences. They replicate real-life operational challenges and require participants to employ lean tools and techniques in a simulated environment. Here are some essential aspects:

- Team Collaboration: These simulations are often played in a group setting, with each person taking on a specific role during the exercise. Participants typically work together, sometimes sitting around a table, to solve problems and improve processes.

- Realistic Scenarios: The games mimic actual workplace situations, allowing participants to experience the impact of lean principles firsthand.

- Hands-On Learning: Participants gain practical knowledge that can be directly applied to their work environments by engaging in these exercises.

Lean manufacturing games can cover many topics, from basic lean principles to advanced process optimization.

The Core Elements of the Games

- Realistic Scenarios: Participants face challenges that closely mimic issues encountered in manufacturing settings, whether managing process bottlenecks, optimizing workflow, or ensuring quality standards. These scenarios are designed to reflect the problems on the shop floor or in production lines.

- Hands-On Learning: Rather than passively listening to lectures, employees actively engage in problem-solving. They experiment with Lean tools—such as 5S and Kaizen—in real-time simulations, bridging the gap between classroom theory and practical application. For example, participants may be asked to draw a fish on paper as a team activity to illustrate concepts like standard work, variation reduction, and the importance of process consistency.

- Immediate Feedback: A key advantage of these games is the ability to provide instant feedback through performance dashboards, graphs, and metrics. Participants can immediately see the effects of their decisions, allowing them to adjust strategies and foster continuous improvement.

- Team Collaboration: Often played in groups, these simulations promote teamwork and interdepartmental communication. Collaborative exercises mirror real-world operating conditions and help build a cohesive work environment, which is crucial for successfully implementing lean strategies.

- Risk-Free Experimentation: Lean manufacturing games create a safe environment where mistakes are treated as learning opportunities rather than failures. This psychologically safe space encourages creativity and reduces the resistance to change that many employees experience in traditional settings.

The Advantages of Lean Manufacturing Games

Enhanced Engagement and Learning Retention

One of the most significant benefits of lean manufacturing games is the level of engagement they foster compared to traditional training methods. When employees are directly involved in decision-making processes, learning becomes:

- Active: Participants take ownership of their learning by facing and solving simulated challenges. This active involvement leads to better retention of lean concepts. Additionally, participants experience a strong sense of accomplishment when they complete a lean manufacturing game or simulation, reinforcing their readiness to apply lean concepts in real-world scenarios.

- Iterative: By cycling through rounds of decision-making and subsequent debriefings, employees experience a continuous improvement loop that mirrors real lean processes. Learn more about practical simulation-based training.

Reduction of Stress and Encouragement of Innovation

Traditional training methods often carry the risk of high-pressure environments where the fear of failure limits creativity. Lean manufacturing games mitigate this by:

- Offering a Safe Space:

Mistakes in a simulated environment do not carry real-world consequences. This risk-free approach reduces stress and anxiety, allowing employees to experiment without fear. - Promoting Innovation:

With reduced pressure, participants are more willing to try out unconventional ideas and creative solutions, which can later be implemented in real operational contexts. - Empowering Growth:

Viewing errors as learning opportunities builds resilience and a growth mindset, essential for continuous improvement.

Explore the benefits of gamification in training.

Strengthening Teamwork and Collaboration

Implementing Lean requires a collaborative effort. Lean manufacturing games are designed to simulate interdependent work environments:

- Enhancing Communication:

Through team challenges, these games compel employees to discuss, plan, and work together to achieve common goals. - Building Trust:

As teams navigate simulated challenges, they build trust and improve cross-functional relationships, which are critical for successful lean implementations. - Reflecting Real Workplace Dynamics:

By mimicking actual operational structures, these games prepare teams to collaborate effectively in the real world.

Driving Cultural Transformation

The ultimate goal of lean manufacturing is not merely to optimize processes but to instill a culture of continuous improvement. Lean manufacturing games contribute to this cultural shift by:

- Empowering Employees:

When employees see tangible improvements from their decisions in a simulation, they become more confident and motivated to apply these principles at work. - Breaking Down Resistance:

Interactive, hands-on experiences help employees overcome the inertia of traditional training methods, paving the way for smoother transitions to lean processes. - Creating a Shared Vision:

Collaborative simulations instill a common understanding and commitment to lean principles across all levels of an organization.

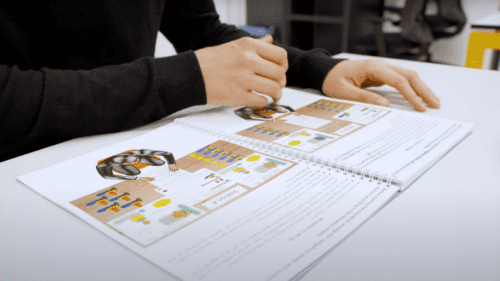

A Closer Look at Get Lean: Our Innovative Simulation Game

Among various lean manufacturing games available today, our Get Lean game stands out as a pioneering solution developed from extensive real-world experience. The Get Lean game and its materials were first published and available for download in 2019. Get Lean is designed to overcome the limitations of conventional training and to directly address challenges such as production losses, inefficiencies, and resistance to change.

Game Mechanics and Structure

- Simulation of Real-World Challenges: Get Lean places players in scenarios that simulate everyday issues like process bottlenecks, material waste, and disorganized workspaces. The game allows participants to experience both push and pull production systems, highlighting the differences between producing based on forecasts (push) and responding to customer demand (pull). Participants are required to implement Lean tools to improve operations step-by-step. One popular 5S training activity involves striking out numbers in sequence or searching for missing numbers within a grid, visually demonstrating the importance of efficiency, organization, and standardization in Lean environments.

- Time-Pressured Decision Making: The game is divided into rounds, each demanding quick decisions that replicate the pressures of a live production environment. For instance, players might need to prioritize improvements based on the impact on productivity and waste reduction.

- Interactive Dashboards: A performance dashboard tracks key metrics such as cycle times, waste percentages, and operational throughput, providing immediate, visual feedback. This allows players to understand the direct effects of their choices and adjust strategies accordingly.

- Role-Based Collaboration: In team modes, each player assumes a distinct role, ranging from process optimization to quality control, mimicking the interdependent nature of lean environments. This structure promotes teamwork and highlights the importance of each function in a successful lean operation.

- Iterative Learning Cycles: Post-simulation debriefing sessions enable teams to discuss outcomes, analyze mistakes, and refine their strategies for subsequent rounds. This reflective practice reinforces learning and helps translate simulated successes into real-world applications.

Distinctive Features of Get Lean

- Real-World Applicability: Developed through years of hands-on experience in lean implementation, Get Lean captures the true challenges and nuances of Lean Manufacturing. The game is built on actual case studies and operational data, making it a reliable training tool.

- Overcoming Psychological Barriers: Get Lean’s low-risk environment allows employees to experiment without fear, facilitating a culture of innovation and improvement. This approach breaks down the resistance to change that often hinders lean implementations.

- Versatility: While targeted initially at manufacturing, Get Lean’s flexibility suits diverse industries, including services and logistics. Its adaptable framework ensures that organizations with varying operational models can benefit from lean principles. Instructors can tailor the game to simulate scenarios based on specific customer demand patterns, allowing training sessions to reflect real-world market needs.

- Engaging and Fun: By transforming serious business challenges into game scenarios, Get Lean injects fun into training, increasing employee engagement and the likelihood of sustained learning.

Please visit our Lean on Game Description page for an in-depth description of Get Lean and its unique benefits.

Practical Benefits and Measurable Outcomes

Reduced Waste and Improved Efficiency

The primary goal of lean manufacturing is to eliminate waste and increase efficiency. Lean manufacturing games simulate real-life scenarios where:

- Waste Identification:

Participants learn to identify waste in various forms, such as overproduction, waiting, transport, excess inventory, unnecessary motion, and defects. - Process Improvement:

By applying Lean tools in the simulation, teams discover practical ways to optimize workflows and minimize losses, leading to measurable cycle times and productivity improvements.

Enhanced Quality and Customer Satisfaction

Implementing Lean effectively leads to enhanced product quality and higher customer satisfaction. Through lean manufacturing games:

- Quality Control:

Participants apply quality improvement techniques that reduce defects and improve service delivery. - Continuous Improvement:

The game’s iterative nature instills a mindset of continuous refinement, ensuring that quality improvements are sustained over time.

Increased Employee Engagement and Collaboration

Employee buy-in is essential for successful lean implementation. Lean manufacturing games, particularly Get Lean, contribute to this by:

- Fostering Active Participation:

Interactive simulations make training engaging, prompting employees to participate in problem-solving actively. - Strengthening Team Dynamics:

Collaborative challenges build trust and improve communication, essential for cross-functional integration. - Empowering Teams:

The hands-on experience boosts confidence in applying Lean principles, making employees more proactive in driving improvements.

Integrating Lean Manufacturing Games into Your Organization

Organizations should adopt a structured approach to training to leverage the full potential of lean manufacturing games like Get Lean. This involves organizing dedicated training sessions where participants can actively engage with the games, practice lean concepts, and enhance their process improvement skills.

If you have questions, find broken links, or want to share additional resources related to lean manufacturing games, please email us.

Assessing Training Needs

- Identify Operational Challenges:

Conduct a thorough analysis of your production or service processes to pinpoint inefficiencies and losses. - Set Clear Objectives:

Define measurable goals—such as reduced cycle times, lower waste levels, and improved quality metrics—that the training should address.

Customizing the Simulation

- Tailor Scenarios to Your Business: Adapt the game’s content to reflect your organization’s specific challenges and operational realities. Provide clear instructions to participants to ensure they understand and can effectively engage with the customized simulation.

- Focus on Critical Lean Tools: Ensure that the simulation emphasizes the lean principles most relevant to your objectives, from waste reduction to process optimization.

Facilitating Debriefing and Continuous Improvement

- Conduct Structured Debriefings: After each simulation round, organize sessions where teams review performance, analyze shortcomings, and discuss actionable strategies.

- Implement Insights: Translate the lessons from the simulation into real-world process improvements, creating a culture of ongoing refinement. Remember, the process of improvement is just beginning after the simulation concludes.

Monitoring and Measuring Impact

- Define Key Performance Indicators (KPIs):

Set metrics to track improvements in efficiency, quality, and employee engagement. - Regular Reviews:

Continuously evaluate the training program’s effectiveness and make adjustments to ensure long-term success.

Overcoming Common Challenges in Lean Game Implementation

Implementing a lean game in your company is an excellent way to introduce and reinforce lean principles, but it’s not without its challenges. One of the most common obstacles is a lack of engagement from team members. Participants may lose interest quickly if a lean game feels disconnected from real work or isn’t fun. To overcome this, making the simulation as interactive and hands-on as possible is essential, incorporating elements that encourage active participation and group collaboration. Simple, engaging activities and a clear sense of purpose can transform a lean game from a routine exercise into a memorable, impactful experience.

Another challenge is ensuring the simulation accurately reflects real-world scenarios. Using straightforward tools and methods—such as physical props or software development platforms—can make it easier to replicate the complexities of your business environment. This approach helps members understand how lean concepts like kaizen and kanban apply to their daily tasks, making the learning process more relevant and effective.

It’s also important to be aware of the potential for resistance when introducing new methods. Some team members may hesitate to try something unfamiliar, especially if they don’t immediately see the value. By clearly communicating the purpose of the lean game and demonstrating how it can help solve real business challenges, you can build buy-in and enthusiasm. Remember, the goal is to teach lean and make the process enjoyable and meaningful for everyone involved.

By anticipating and proactively addressing these challenges, your company can implement lean games that genuinely make a difference, boosting engagement, deepening understanding, and driving continuous improvement across the organization.

Best Practices for Maximizing Lean Game Success

To ensure your lean games deliver maximum impact, follow best practices that make the experience compelling and enjoyable. Start by defining clear objectives for each game—understand exactly what you want participants to learn and how these goals align with your company’s broader lean journey. When everyone knows the purpose, staying focused and measuring success is easier.

Simple rules and a straightforward method of play help participants quickly grasp the concepts, making it easier for them to engage and apply what they learn. An experienced instructor or facilitator is also key; they can guide the group, answer questions, and ensure the game stays on track, maximizing learning for every member.

After the game, a debriefing session is always held. This crucial step allows participants to reflect on their experiences, discuss what worked, and identify areas for improvement. Debriefing helps solidify understanding of lean principles and encourages teams to consider applying these lessons in real work situations—whether it’s Lean Six Sigma, Kaizen, or Kanban.

By following these best practices, your company can create lean games that are easy and fun to play and highly effective in teaching lean principles and driving real business results.

Expanding Lean Game Applications: Advanced Lean Concepts in Action

Lean games are not limited to teaching foundational lean principles—they are also an excellent way to bring advanced lean concepts to life. By simulating complex scenarios, these games help participants and teams deepen their understanding of lean methodologies and see firsthand how advanced techniques can drive efficiency, quality, and continuous improvement. Whether you aim to teach Lean Six Sigma, optimize work cell layouts, or embed quality at every step, lean games provide a dynamic, hands-on platform for learning and applying these powerful concepts.

Work Cell Design and Optimization: Simulating Efficient Layouts

Work cell design is a cornerstone of lean manufacturing, and lean games offer a hands-on way to explore and optimize this concept. Through interactive simulations, teams can experiment with different work cell layouts, testing how configuration changes affect process flow, lead times, and overall productivity. Participants might be asked to design a work cell that supports one-piece flow, reduces unnecessary movement, and maximizes space utilization. By simulating these scenarios, teams quickly see the impact of their decisions, learning how to create efficient, waste-free work cells that support lean objectives. This practical experience helps participants understand the importance of layout in achieving smooth, continuous flow and sets the stage for real-world improvements.

Batch Size Reduction Strategies: Experiencing the Power of Small Lots

Reducing batch sizes is a key lean strategy for minimizing waste and improving responsiveness. Lean games can vividly demonstrate the advantages of small batch production by allowing teams to compare the outcomes of different batch sizes in a controlled, hands-on environment. Participants might play a game where they produce items in large batches, then switch to smaller batches or even one-piece flow, tracking the effects on inventory, lead time, and defect rates. This direct experience helps teams understand how smaller batch sizes lead to faster feedback, lower inventory costs, and higher quality. By seeing the results in real time, participants are better equipped to implement batch size reduction strategies in their processes, driving lean improvements across the organization.

One Piece Flow and Production: Bringing Continuous Flow to Life

One-piece flow is a fundamental lean concept that emphasizes producing items one at a time, moving smoothly from one process step to the next. Lean games are an excellent way to simulate and teach this principle, allowing participants to experience the benefits of continuous flow firsthand. In a typical game, teams might be assigned specific tasks along a simulated production line, working together to achieve a seamless flow of products. As participants adjust their approach to eliminate bottlenecks and synchronize their efforts, they quickly see how one-piece flow reduces lead times, cuts inventory, and boosts customer satisfaction. This immersive learning experience helps teams internalize the value of continuous flow and prepares them to implement it effectively in their work environments.

Real-World Results: Case Studies in Lean Manufacturing Games

The actual value of lean games is best seen in real-world results. Many companies have used these simulations to improve costs, efficiency, and customer satisfaction significantly. For example, a major automotive manufacturer implemented a lean game to simulate their production line, allowing team members to identify bottlenecks and experiment with process changes in a risk-free environment. The result? The company managed to reduce waste, streamline their workflow, and achieve measurable cost savings—demonstrating the power of a simple, hands-on way to learn and apply lean principles.

In another case, a food processing company used a lean game to improve its supply chain management. By simulating different order and delivery scenarios, team members could compare the impact of various strategies, adapt to changing demand, and implement more efficient pull systems. This led to shorter lead times, improved delivery performance, and higher customer satisfaction, proving that lean games can drive continuous improvement across the entire business.

These case studies highlight how lean games—whether short games focused on a single process or more complex simulations covering the entire value stream—can help companies achieve their business goals. By making learning fun, interactive, and directly connected to real work, lean games empower every person and team member to contribute to ongoing improvement. Whether you’re looking to implement Lean Six Sigma, introduce kaizen, or make your processes more efficient, lean games offer a proven, effective way to teach lean, record progress, and deliver lasting results.

If you’re ready to see how lean games can transform your company, remember that the best way to learn is by doing. Start small, keep things simple, and let every round of the game bring you closer to your goals for efficiency, quality, and customer satisfaction.

The Future of Lean Manufacturing Games

As digital transformation continues to evolve, lean manufacturing games are set to become an integral part of corporate training. These games are increasingly used in software development environments to teach lean principles and improve workflow efficiency. Computer-based simulations are becoming more common, allowing remote and digital training sessions to be accessed from anywhere. Instructional videos also effectively demonstrate lean games and simulations, providing step-by-step guidance and real-life examples. Anticipated trends include:

- Enhanced Immersive Technologies: Virtual reality (VR) and augmented reality (AR) will create even more lifelike training simulations.

- Global Adaptation: Tools like Get Lean are ideal for multinational organizations because they support multiple languages and provide culturally tailored content.

- Data-Driven Optimization: Advanced analytics will facilitate real-time performance monitoring, enabling continuous enhancements to training programs.

- Blended Learning Models: Combining lean manufacturing games with traditional training methods and e-learning platforms will provide comprehensive professional development ecosystems.

Conclusion

Lean manufacturing games are revolutionizing how organizations train their workforce by combining interactive, hands-on learning with the robust demands of Lean Manufacturing implementation. Get Lean, our innovative simulation game, exemplifies this transformation by turning abstract concepts into practical actions that directly address operational challenges and reduce losses. Drawing on extensive real-world experience, Get Lean demonstrates the benefits of Lean principles and helps overcome the psychological barriers that often impede change.

By enabling employees to experiment in a risk-free environment, fostering teamwork, and providing immediate, actionable feedback, Get Lean embeds continuous improvement into your organization’s DNA. The measurable benefits—from enhanced operational efficiency to improved quality and stronger cross-functional collaboration—underscore its potential to drive lasting, transformative change.

Exclusive Offer: When you purchase our simulation tool, you’ll receive a complimentary access code that unlocks all our online Lean training courses—completely free of charge. It’s the perfect way to extend your learning journey without any additional investment.

You’ll gain instant access to popular courses such as:

👉 Effective Problem-Solving Process

👉 5S Workplace Organization

👉 Continuous Improvement Mastery

👉 Teamwork & Leadership in Lean

Please visit our Lean on Game Description page for a comprehensive look at Get Lean’s features and benefits. The simulation supports six languages, making it ideal for global organizations pursuing consistent, high-impact lean training.