Lean Simulation: A Practical Approach to Mastering Lean Principles

Introduction to Lean Principles

Lean principles are a robust set of guidelines designed to help organizations maximize customer value while minimizing waste across all processes. Whether in manufacturing, logistics, or service industries, the lean approach focuses on delivering more value to customers by streamlining operations, eliminating unnecessary steps, and continuously improving every aspect of the business.

At the heart of lean thinking is the drive for continuous improvement. This means constantly evaluating processes to identify and eliminate waste, whether wasted time, resources, or effort. By focusing on what truly matters to the customer, companies can reduce costs, improve quality, and boost customer satisfaction, all while increasing labor productivity and efficiency.

Applying lean principles isn’t limited to the shop floor. Organizations can implement lean concepts in production, administration, logistics, and even customer service, transforming themselves into lean producers. The key is a deep understanding of existing processes and the ability to spot opportunities for improvement. This often involves using proven lean techniques such as value stream mapping, standardized work, and visual controls to make material and information flow more efficiently, resulting in better decision-making and faster lead time reductions.

One of the most effective ways to teach and reinforce lean principles is through lean games and simulations. These interactive training sessions allow teams to experience the impact of lean concepts firsthand, making learning engaging and practical. By participating in simulations, employees gain the skills and confidence needed to identify problems, implement solutions, and foster a culture of continuous improvement.

Lean principles also complement other management methodologies like Six Sigma and Total Quality Management, providing a comprehensive toolkit for organizations aiming to achieve operational excellence. When effectively applied, lean principles can significantly improve quality, labor productivity, and customer satisfaction, helping companies improve their competitiveness and deliver greater value to their customers.

By embracing lean thinking and focusing on continuous improvement, organizations can transform their processes, reduce waste, and create lasting benefits for their teams and customers.

What is Lean Simulation?

Lean simulation is a hands-on learning method that helps teams understand, apply, and demonstrate Lean principles in a realistic, risk-free setting. By recreating real-world processes through simulations, participants explore key lean concepts like waste reduction, flow optimization, and value creation. These training sessions offer an engaging and interactive way to develop practical Lean skills, with attendees actively participating in the simulation to enhance learning. Lean simulations teach participants how lean principles can be applied to improve processes and reduce waste. Lean simulation is also an effective teaching tool for illustrating Lean concepts in practice.

In a Lean simulation, participants take on different roles within a simulated organization—from operators to quality control inspectors—working together to improve customer satisfaction, reduce costs, and apply continuous improvement techniques. The ability of each person to influence outcomes highlights how individual engagement and learning outcomes are essential in the simulation, demonstrating how individual skills impact the overall process. The goal is to learn Lean principles and practice and demonstrate their effectiveness.

If you’re ready to strengthen your Lean skills, explore our Lean Management course—a practical program designed with 25 years of Lean experience.

How the Get Lean Simulation Game Works

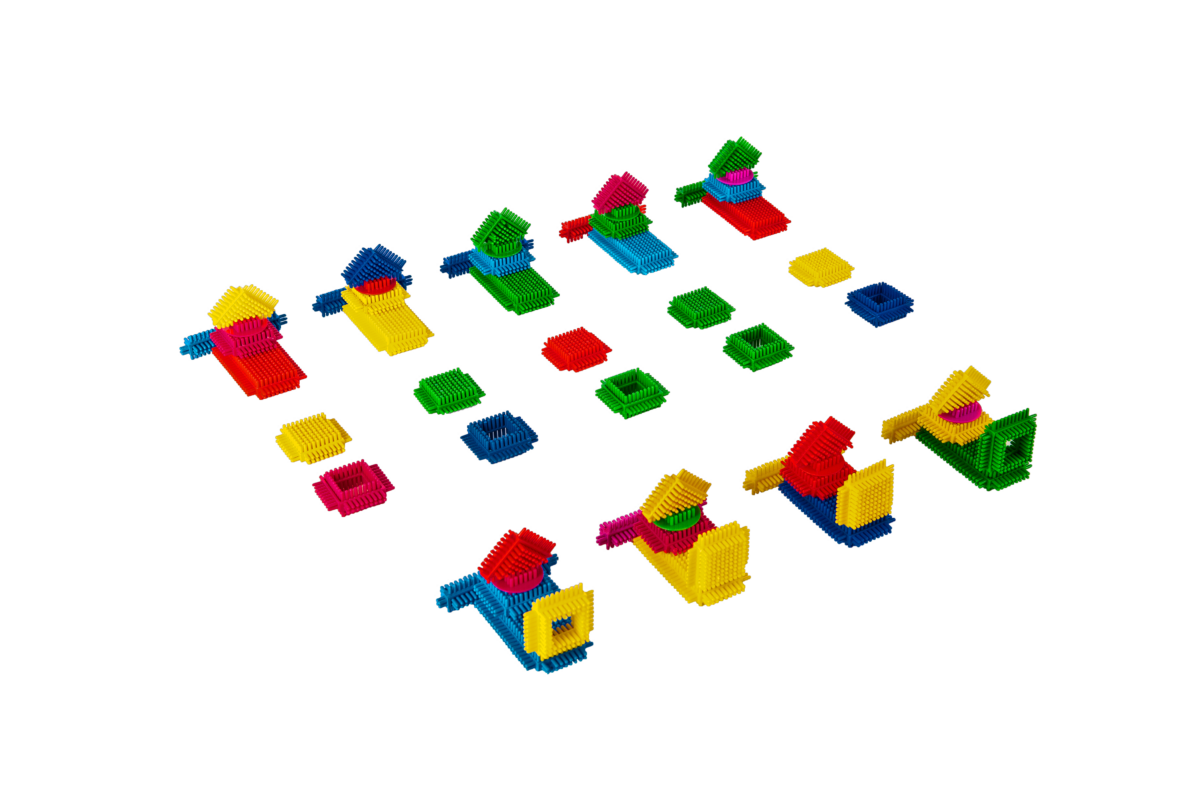

The Get Lean Simulation Game is a leading Lean simulation tool that reflects companies’ real challenges. It simulates a company called “Progression”, which produces plastic parts using hedgehog blocks in various shapes and colors. Participants gather around a table to collaborate and face tasks like fulfilling customer orders with 100% accuracy, working to minimize waste, and meeting a strict production cost target of $40 per unit.

The game comprises up to six sessions, each representing 10 customer orders. Participants run multiple rounds or iterations of the simulation to reinforce learning. After each session, teams can stop production to reflect, discuss, and introduce Lean tools like value stream mapping, standardized work, pull systems, and pull scheduling. During gameplay, teams find key lean concepts or constraints that impact their process. The simulation also integrates scheduling techniques to optimize workflow and reduce lead times. This approach mirrors how Lean improvements are implemented in real companies, allowing participants to apply problem-solving and continuous improvement techniques immediately.

Participants play various roles, including Kaizen leader, line manager, warehouse manager, quality control, and internal logistics. Together, they learn how to manage flow, reduce batch sizes, and adapt to changing customer demands. The simulation demonstrates the concept of one-piece flow, showing how moving materials one unit at a time through each process step increases efficiency and reduces waste. The game uses everyday materials like colored paper, plastic blocks, and clear rules, with the option to add supplemental components to enhance the experience and teach Lean through practice.

When fulfilling customer orders, it is essential to ensure they are complete before proceeding to the next session. The simulation can be adapted for different industries, such as packaging or electronics, to demonstrate its versatility.

Want to deepen your understanding of Lean tools and principles? Take our Effective Problem Solving and Continuous Improvement courses.

Why Lean Simulations Work

Lean simulations are an effective way to learn because they:

- Provide a practical application of Lean principles.

- Encourage teams to collaborate, communicate, and problem-solve by engaging participants in a fun simulation.

- Create a safe space to learn from mistakes and refine solutions.

- Reinforce Lean thinking through discussion, reflection, and action, prompting participants to ask questions and think critically about Lean concepts.

- Help participants understand the impact of their decisions on flow, quality, and customer satisfaction.

Lean simulations suit various training environments and group sizes, making them adaptable to different learning objectives.

Explore our 5S Workplace Organization course and Effective Teamwork and Leadership course for structured Lean learning.

Key Benefits of Lean Simulation

- Hands-on learning: Learn Lean principles by applying them in simulated scenarios, striving for the perfect process flow and optimal outcomes.

- Collaborative teamwork: Build strong communication and teamwork skills.

- Real-world problem solving: Address realistic challenges like bottlenecks and waste.

- Engaging format: Make learning Lean an enjoyable and practical experience.

- Focus on customer value: Align activities with customer satisfaction goals.

- Visual management tools: Use post-it notes and boards to map and organize workflows during simulations.

Start with the Lean Management course to dive deeper into Lean concepts and tools.

Continuous Improvement Strategies: Turning Simulation Insights into Action

Continuous improvement is at the heart of lean manufacturing, and simulations are a powerful catalyst for making real, lasting change. By leveraging lean games and simulation exercises, organizations can transform insights into practical actions that drive better quality, reduced waste, and higher customer satisfaction. Here’s how to turn your simulation experience into a roadmap for continuous improvement:

- Identify Key Areas for Improvement. Start by analyzing the results from your lean simulation. Use lean thinking to pinpoint bottlenecks, sources of waste, and inefficiencies in your processes. Focus your team’s efforts on the most critical areas where improvements will significantly impact customer satisfaction and operational performance.

- Develop a Plan for Implementation. Once you’ve identified improvement opportunities, create a clear action plan. Set specific goals, define objectives, and establish timelines. Lean tools like value stream mapping and standardized work help teams visualize the process, align on priorities, and ensure everyone is working toward the same targets.

- Provide Training and Support. Equip your team with the knowledge and skills needed to succeed. Use lean games, simulations, and targeted training sessions to deepen understanding of lean principles and continuous improvement techniques. Ongoing support ensures that everyone can confidently apply new methods and drive results.

- Monitor Progress and Evaluate Results: Track key metrics such as quality, delivery, and cost to measure the impact of your changes. Lean tools like Kanban and pull systems help teams visualize workflow and identify new opportunities for improvement. Regularly reviewing results keeps the team focused and agile.

- Encourage a Culture of Continuous Improvement. Foster an environment where continuous improvement is part of everyday work. Recognize team achievements, provide growth opportunities, and encourage open discussion of new ideas. A culture that values lean principles ensures that improvements are sustained over time.

- Use Simulations to Drive Ongoing Improvement. Lean simulations and games aren’t just for training—they’re valuable tools for ongoing problem solving. Use them to test new ideas, model different scenarios, and refine your processes before making changes on the shop floor. This approach reduces risk and accelerates learning.

- Apply Lean Principles to New Areas. Lean thinking can be expanded beyond manufacturing by applying lean concepts and continuous improvement techniques to sales, delivery, service, and other business functions. This holistic approach helps the organization benefit from reduced waste, improved flow, and greater customer value.

- Continuously Review and Refine Processes. Make process review a regular part of your lean journey. Use value stream mapping and standardized work to identify new areas for improvement and keep your processes efficient and effective. Continuous refinement ensures your organization stays competitive and responsive to change.

By following these strategies and using lean games and simulations as a springboard for action, your organization can unlock the full benefits of lean manufacturing. Improved quality, reduced costs, and higher customer satisfaction are within reach, whether you’re just starting or looking to take your lean journey to the next level. Embrace lean principles, empower your teams, and transform your processes for lasting success.

Essential Lean Tools and Techniques: Building Your Simulation Toolkit

To truly master lean manufacturing and drive meaningful change, building a strong foundation in the essential tools and techniques that underpin lean principles is crucial. These methods are the backbone of any successful lean approach, enabling organizations to maximize customer value, minimize waste, and transform their processes for lasting results.

Key lean tools like value stream mapping, cellular manufacturing, and pull scheduling are at the heart of practical lean thinking. Value stream mapping allows teams to visualize every process step, making it easier to identify bottlenecks, eliminate waste, and streamline information flow. Cellular manufacturing organizes workstations into efficient cells, reducing floor space requirements and manufacturing lead times while boosting labor productivity. Pull scheduling ensures that production is driven by customer demand, helping companies reduce inventories, improve delivery performance, and focus on what truly matters to the customer.

Lean games and simulations bring these concepts to life in a fun, interactive way. By participating in hands-on training sessions, teams can experience firsthand how lean principles work in practice. These simulations demonstrate the power of standardized work and visual controls, showing how clear guidelines and real-time feedback can help eliminate waste, improve quality, and foster a culture of continuous improvement. Participants learn to apply one-piece flow, quality at the source, and other lean techniques, gaining the confidence and skills needed to drive change in their organizations.

Continuous improvement techniques are central to the lean approach. By focusing on ongoing process refinement, companies can achieve significant lead time reductions, reduce costs, and increase customer satisfaction. Lean training sessions and simulations provide a safe environment for teams to practice problem-solving, experiment with new ideas, and develop a deep understanding of lean concepts. This hands-on experience is invaluable for building the ability to apply lean principles effectively in daily work.

Becoming a lean producer requires more than just adopting new tools—it demands a shift in mindset. Organizations must be willing to transform traditional manufacturing processes, embrace standardized work, and focus relentlessly on customer value. By leveraging lean tools and techniques, such as simulation and modeling, companies can analyze and improve their processes, increasing efficiency, productivity, and quality.

Incorporating lean games and simulations into your training programs is a powerful way to teach participants about lean manufacturing, continuous improvement, and problem-solving. These engaging activities help teams understand how to identify and eliminate waste, optimize flow, and deliver greater value to customers. With a solid grasp of lean tools and techniques, your organization will be well-equipped to achieve its objectives, reduce costs, and drive continuous improvement across all business areas.

The Get Lean Simulation Game: Your Gateway to Lean Learning

The Get Lean Simulation Game is a practical learning experience based on 25 years of hands-on Lean consulting. It offers a structured, step-by-step process for mastering Lean principles, including value stream mapping, cellular manufacturing, pull systems, and continuous improvement techniques.

Participants who purchase the Get Lean Simulation Game will receive a special email code granting free access to all of Sabat Consulting’s Lean training courses, including:

- Lean Management course

- Effective Problem-Solving Course

- Continuous Improvement course

- Effective Teamwork and Leadership course

- 5S Workplace Organization course

During the simulation, inefficiencies can be found and addressed, helping your team identify and resolve process issues in real time.

This offer allows you to expand your Lean knowledge across multiple topics and build the skills you need to drive organizational transformation.

Ready to start? Explore the Get Lean Simulation Game and unlock your path to Lean mastery today!