Training Lean Management: A Strategic Investment in Operational Excellence

In the rapidly evolving business world, training lean management has become essential for companies aiming to thrive in competitive markets. Lean thinking is no longer confined to manufacturing floors; it has expanded into healthcare, services, software development, and public administration. Lean management training is aimed at leaders and professionals responsible for driving organizational improvement and influencing company culture. As organizations seek to boost operational efficiency, reduce waste, and create value for customers, a company can benefit from lean management training through improved efficiency and inventory management. Structured lean management training programs emphasize education as the foundation for acquiring the knowledge and skills required to lead transformative change.

Why Training Lean Management Matters

Lean management is a methodology focused on maximizing customer value while minimizing waste. To apply lean principles effectively, organizations must ensure their employees—from front-line operators to senior executives—have the necessary skills, knowledge, and mindset. This is where formal training plays a critical role. After completing training, participants will feel confident applying lean tools and driving meaningful change within their organization.

Key reasons why training lean management is crucial include:

- Accelerating process improvement initiatives that benefit the entire organization by fostering a culture of improvement and efficiency.

- Promoting a culture of continuous improvement and problem solving.

- Enabling employees to understand and implement lean tools effectively.

- Enhancing customer satisfaction by improving quality and response times.

- Achieving operational excellence and sustained growth.

Lean Thinking and Culture

Lean thinking is more than a set of tools—it’s a philosophy that drives organizations to eliminate waste and pursue continuous improvement in every process. At its core, lean thinking encourages companies to focus on value creation, respect for people, and relentless problem solving. By embedding these lean principles into daily operations, organizations can foster a culture that supports operational excellence and sustainable growth.

A lean culture is essential for achieving manufacturing excellence and gaining a competitive advantage. Companies that embrace lean thinking see significant improvements in productivity, quality, and customer satisfaction. This transformation is supported by strategic deployment methods such as Hoshin Kanri for aligning goals, A3 Problem Solving for structured improvement, and Daily Management Systems for consistent performance tracking.

Developing a solid understanding of lean principles and methodologies empowers organizations to create a culture where continuous improvement is second nature. As teams internalize these values, they become more agile, innovative, and capable of driving lasting change across all levels of the business.

Core Topics in Lean Management Training

A comprehensive lean management training program covers various topics to address different aspects of lean thinking. Some certification programs are considered the gold standard in the industry, recognized for their rigorous assessment process and comprehensive coverage. These typically include:

1. Lean Principles

Understanding the five core lean principles—value, Value Stream, Flow, Pull, and Perfection—is foundational. These principles are the backbone of any lean transformation and guide all process decisions.

2. Value Stream Mapping

This critical lean tool helps visualize and analyze the materials and information required to bring a product or service to a consumer. It supports process optimization and identifies non-value-added activities.

3. Lean Tools and Techniques

Training often includes hands-on instruction in tools such as 5S, Kaizen, Kanban, Poka-Yoke, and TPM. These tools aid in improving quality control, reducing waste, and standardizing operations.

4. Lean Six Sigma Integration

Many training programs combine lean with Six Sigma to drive efficiency and reduce variation. This powerful integration supports advanced process improvement and problem-solving techniques. Organizations can consistently achieve leading efficiency and customer satisfaction standards by applying Lean Six Sigma.

5. Change Management and Leadership

Managers must be trained in technical tools, change management, communication, and leadership skills to lead a successful lean journey. Effective leaders play a pivotal role in sustaining lean transformations.

Employee Engagement and Motivation

Employee engagement and motivation are at the heart of a successful lean journey. Lean methodologies, including Six Sigma and Lean Six Sigma, emphasize the critical role of employee involvement in process improvement. When actively engaged employees contribute valuable insights, drive innovation, and help identify opportunities to enhance productivity and quality.

Companies prioritizing employee engagement experience higher levels of customer satisfaction and operational excellence. Lean tools such as visual management boards and real-time feedback systems empower employees to participate in continuous improvement efforts, making them feel valued and respected.

A lean culture that fosters open communication and recognizes employee contributions creates a positive and productive work environment. Organizations that invest in motivating and engaging their teams are better positioned to achieve a competitive advantage, sustain improvement initiatives, and realize the full benefits of lean management.

Types of Training Formats Available

Organizations can choose from various training formats, depending on their size, maturity, and strategic goals:

- In-person workshops and seminars for immersive, hands-on learning.

- Online courses that offer flexible learning schedules to accommodate different learners and global access.

- Hybrid programs combine virtual modules with live sessions.

- Certification programs are recognized across industries.

It is essential to fully complete training programs to achieve mastery and certification.

Many organizations invest in online training to accommodate global teams and ensure consistent learning outcomes across regions. These courses allow professionals to learn independently while applying concepts directly to ongoing projects. By completing these courses, participants gain the skills to apply lean tools effectively in their organizations.

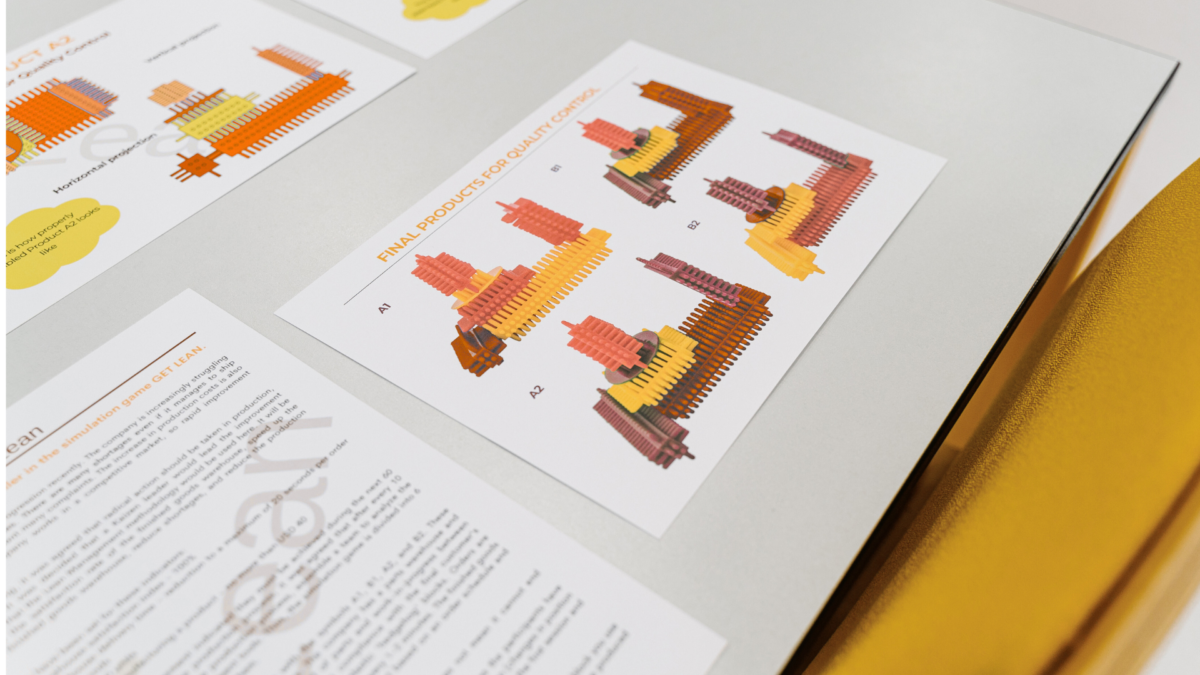

Real-World Application: The GET LEAN Simulation Game

The GET LEAN simulation game is an example of experiential learning in lean management training. This interactive training tool places participants in a simulated production environment where they must apply lean principles in real time. Through six dynamic rounds, players identify waste, implement changes, and improve processes using techniques like pull systems, work cell layouts, and standard work.

Key benefits of GET LEAN include:

- A highly hands-on approach that enhances engagement.

- Reinforcement of theoretical knowledge through practical exercises.

- Encouragement of team collaboration and cross-functional thinking.

- Exposure to real-world challenges in a risk-free environment.

GET LEAN participants consistently report a deeper understanding of lean methodologies, increased confidence in applying lean tools, and better alignment between training and workplace practices.

For more about this engaging tool, visit the official GET LEAN Game Description page.

Technology and Innovation in Lean Training

Technology and innovation are transforming the landscape of lean training and development. Online courses and certification programs like Lean Principles Certification provide professionals and organizations with flexible access to essential lean knowledge and skills. These digital learning platforms enable participants to develop expertise in lean methodologies at their own pace, regardless of location.

Integrating digital tools and platforms enhances the learning experience, making it more interactive and practical. Innovations like Industry 4.0 technologies also reshape lean methodologies, helping companies eliminate waste, reduce costs, and achieve manufacturing excellence.

Organizations that invest in technology-driven lean training benefit from improved productivity, higher quality, and increased customer satisfaction. By leveraging the latest advancements in training and development, companies can ensure their teams are equipped with the skills needed to stay ahead in a competitive market and drive continuous improvement across all processes.

Measuring Success and Evaluating Progress

Measuring success and evaluating progress are fundamental to any effective lean management system. Organizations rely on key performance indicators (KPIs) such as lead time, throughput, and quality to assess the impact of their lean initiatives. These metrics provide valuable insights into operational efficiency and highlight areas for further improvement.

Lean tools like dashboards and scorecards enable companies to track and analyze real-time performance data, supporting informed decision-making and strategic planning. Applying lean methodologies, including Six Sigma and lean Six Sigma, helps organizations identify, prioritize, and address process bottlenecks and inefficiencies.

A solid understanding of lean principles and methodologies is crucial for developing effective measurement and evaluation systems. Companies regularly monitoring their progress are more likely to achieve operational excellence, gain a competitive advantage, and sustain long-term improvement.

Customer Satisfaction and Loyalty

Customer satisfaction and loyalty are central to any successful business strategy, and lean methodologies strongly emphasize meeting and exceeding customer expectations. Lean Six Sigma and other process improvement approaches prioritize customer focus, ensuring that every improvement initiative is aligned with delivering greater value.

Companies prioritizing customer satisfaction benefit from higher retention rates, increased growth, and a stronger competitive position. Lean tools such as voice of the customer (VOC) analysis and customer feedback systems help organizations better understand and respond to customer needs.

Creating a lean culture that values and respects customers is essential for building lasting loyalty and trust. Organizations consistently delivering high-quality products and services through lean management are better equipped to achieve operational excellence and stand out in the marketplace.

Benefits of Investing in Lean Management Training

Companies that prioritize training lean management enjoy measurable improvements in both culture and performance. These include:

- Improved operational efficiency through streamlined workflows.

- Reduced waste and cost savings across departments.

- Higher employee engagement due to empowerment and clarity.

- Faster decision-making thanks to standardized practices.

- Sustained competitive advantage through agility and innovation.

By fostering a lean culture, organizations are better equipped to navigate disruptions, scale operations, and meet evolving customer demands.

Choosing the Right Training Program

When selecting a lean management training program, organizations should consider the following:

- Does the course include real-life case studies and simulations?

- Are instructors experienced lean practitioners?

- Is there a certification path?

- Can the training be customized for specific industries?

- Does the program offer follow-up support or mentoring?

Courses like Sabat Consulting’s Lean Management training offer precisely these features, making them an excellent choice for teams and professionals.

Final Thoughts: Lean Management Training That Drives Real Change

Training Lean Management isn’t just about transferring knowledge—it’s about changing how people think and work. That’s why Lean games are so powerful: they transform passive learning into active participation and give your team the space to practice improvement in action.

Through realistic simulations, teams develop a deep understanding of Lean principles like flow, pull, standardization, and continuous improvement—not just in theory, but in real time.

✅ Whether rolling out Lean across your company, onboarding new hires, or building a continuous improvement culture, simulation-based learning is one of the most effective ways to train Lean Management with lasting results.

🎯 Want to make Lean training practical, engaging, and results-driven? Discover the GET LEAN Simulation and see how it fits your training strategy.

🎁 Complete Your Lean Management Training with Free Online Courses

When you purchase the simulation tool, you’ll unlock free lifetime access to a complete suite of Lean e-learning courses—ideal for reinforcing core concepts and building capability across your organization.

Included in your bonus training package:

-

Effective Problem-Solving Process – Teach teams to identify root causes and implement long-term solutions.

-

5S Workplace Organization – Provide practical tools to organize, standardize, and improve the workspace.

-

Continuous Improvement Mastery – Help leaders and teams establish a sustainable CI system.

-

Teamwork & Leadership in Lean: The collaboration and leadership skills required to support Lean from the ground up.

These online courses perfectly complement your hands-on Lean Management training, creating a blended learning journey that drives understanding and implementation.