Spis treści

Lean manufacturing is more than a set of tools—it’s a philosophy aimed at creating more value for the customer with fewer resources. The lean production system, historically developed from the Toyota Production System (TPS), represents a comprehensive framework for efficient manufacturing that has influenced industries worldwide.

Rooted in the Toyota Production System (TPS), developed by Toyota Motor Corporation, lean manufacturing has transformed the way companies design production processes and build products, sparking a global shift toward efficiency and continuous improvement. Early influences on lean manufacturing include scientific management, pioneered by Frederick Winslow Taylor, which emphasized process analysis and efficiency. Over time, lean production evolved from the principles established in the Toyota Production System, focusing on waste reduction, continuous improvement, and maximizing value.

Origins: The Toyota Production System & Lean Manufacturing

The journey begins with the Toyota Production System, also known as the “Toyota Way.” Mass production methods, which emphasized economies of scale and low costs, heavily influenced the development of TPS as Toyota sought to improve upon these traditional approaches. Beginning in post-war Japan, TPS focused on two pillars: just-in-time manufacturing and continuous quality control. Its core purpose was to eliminate waste—or “muda“—from every part of the production cycle. In refining TPS, Toyota continually improved its productive processes to boost efficiency and reduce waste. The evolution of the production line played a central role in optimizing workflows and responsiveness to demand.

Lean manufacturing emerged from TPS, formalized in the late 1980s by John Krafcik and later popularized by Womack and Jones in “Lean Thinking”. Unlike traditional manufacturing resource planning systems, which used forecasts to drive production and inventory, lean manufacturing adopted a pull-based approach that responded directly to customer demand. Production scheduling also shifted from push systems, driven by predictions, to pull systems that prioritized actual demand, thereby further enhancing efficiency and reducing waste.

Defining Lean Manufacturing

Understanding lean manufacturing is essential for grasping its origins, core principles, and significance in modern production practices.

At its core, lean manufacturing is a production system designed to:

- Eliminate waste

- Minimize production costs

- Improve quality and responsiveness

- Increase customer satisfaction

- Deliver value just in time

The lean philosophy, rooted in the Toyota Production System, serves as the foundation of lean manufacturing by emphasizing the elimination of waste, continuous improvement, and creating value for customers. Lean manufacturing systems represent comprehensive approaches to optimizing production efficiency and reducing waste. Lean methods are now applied across various industries, including healthcare, IT, and the public sector, to drive process improvement and efficiency. While lean manufacturing focuses on production, the lean enterprise extends these principles across all departments and strategic operations, integrating practices like lean accounting to support organization-wide transformation.

Meaningful adoption extends beyond process changes—it transforms organizational culture and decision-making.

The Five Key Principles of Lean Manufacturing

Womack and Jones summarized the essence of lean into five core principles. Waste elimination is a core principle and lean principle of lean manufacturing, guiding organizations to maximize productivity and reduce non-value-adding activities:

- Value – Specify value from the customer’s perspective

- Value stream mapping – Map the value stream to see all steps in the production process, and eliminate waste

- Flow – Create flow and focus on creating flow to ensure continuous movement in production processes

- Pull system – Establish a pull system to produce only in response to customer demand

- Perfection – Pursue perfection and focus on continuous improvement by never stopping continuous improvement

Implementing these lean manufacturing principles builds a lean manufacturing system that adds value at every step.

Why Lean Manufacturing Matters

1. Eliminating Waste

Waste—whether excess inventory, idle equipment, or over-processing—represents inefficiency. Lean focuses on eliminating these inefficiencies to reduce costs and improve responsiveness.

In addition to the original seven wastes, lean manufacturing also recognizes the ‘eighth waste’, which refers to the unused talent and ingenuity of workers. Addressing this waste is essential for continuous improvement and maximizing value.

2. Efficiency & Quality

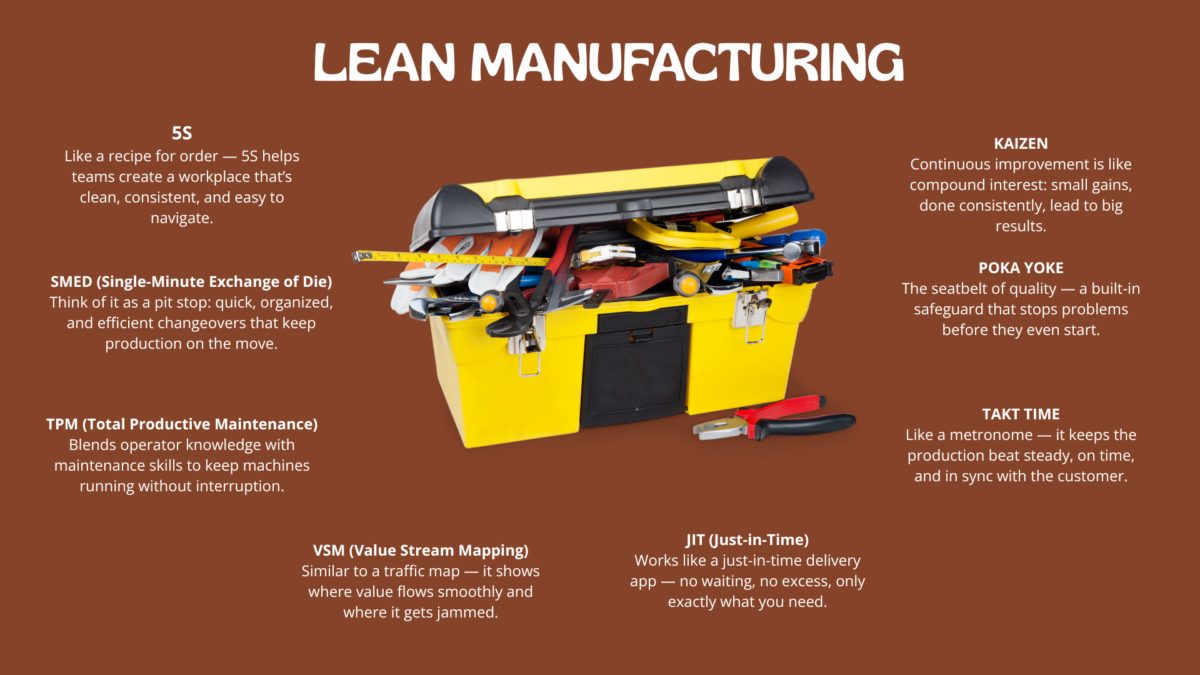

Lean improves flow, balances production processes, and incorporates lean tools such as 5S, Kanban, Poka-Yoke, and Total Productive Maintenance (TPM). Lean manufacturing plants are characterized by high efficiency, minimal waste, and a strong focus on continuous improvement.

3. Customer Satisfaction

By aligning production closely with customer demand, companies reduce lead time and excess inventory, while improving delivery accuracy and quality. Lean manufacturing focuses explicitly on meeting customer demands by synchronizing production and resources, thereby minimizing waste and enhancing responsiveness.

4. Sustainable Growth

A lean manufacturing system drives operational excellence—not just in manufacturing plants but across the entire supply chain, fostering continuous, sustainable improvements.

By adopting lean principles throughout the organization, companies can transform into a lean enterprise, integrating lean thinking into all departments and strategic operations for greater overall impact.

These lean practices help create wealth by optimizing value streams, reducing waste, and improving profitability through more efficient resource utilization.

The “Just-in-Time” Principle and Pull Systems

A hallmark of lean manufacturing is just-in-time (JIT) production, which ensures goods are produced on demand in response to customer needs. This reduces inventory management costs and enables tighter synchronization across suppliers.

Lean manufacturing shifts production scheduling from traditional push systems, which are driven by forecasts, to pull systems that respond directly to actual demand. Pull systems and Kanban signals enable this demand-driven flow, helping prevent both overproduction and stockouts. To further optimize efficiency and reduce inventory, lean frameworks use production leveling (Heijunka) to smooth out fluctuations in demand and create a steady production flow. One of the core principles of lean is to establish a pull system, ensuring that work begins only when there is actual demand, which increases flexibility and responsiveness in production processes.

Lean Manufacturing Tools & Techniques

Lean uses a variety of lean manufacturing techniques and lean tools, including:

- Value stream mapping – visualize and optimize value stream; to effectively identify waste and opportunities for improvement, it is essential to map the value stream across all processes

- 5S – workplace standardization

- Kaizen – continuous improvement events

- Kanban – signaling for workflow control

- Poka-Yoke – error prevention

- TPM – proactive maintenance

Lean practitioners use these tools to drive improvement and highlight additional wastes, such as the waste of unused talent and ingenuity. Lean methods are applied across various industries to optimize processes, minimize waste, and enhance efficiency.

These tools play a vital role in eliminating waste and creating a continuous flow from raw materials to the customer.

Implementing Lean in the Real World

Understanding the meaning of lean manufacturing is just the beginning. To successfully implement lean manufacturing, follow these steps:

- Mapping the value stream

- Removing non-value steps

- Establishing pull systems and adopting pull-based scheduling

- Standardizing work and minimizing variation

- Adopting continuous improvement as a system-wide culture

Cross-functional teams, executive sponsorship, and consistent use of lean manufacturing tools are key enablers.

Case in Point: GET LEAN Simulation & Training

To truly internalize lean principles, hands-on practice is effective. The GET LEAN Simulation Game immerses teams in a realistic production process, where players apply lean manufacturing techniques, test pull systems, and discover value stream mapping in action. The simulation helps participants understand and improve manufacturing processes by allowing them to identify inefficiencies and implement solutions in a controlled environment. It also demonstrates the principles of lean production in action, showing how waste reduction and continuous improvement can be achieved. Through hands-on practice, the training enables teams to improve manufacturing processes by applying lean concepts directly to workflow challenges.

Combine it with our Lean Management Course to combine theory, tools, and practice, accelerating your lean transformation.

Lean Manufacturing Beyond Just Manufacturing

Although rooted in industrial production, lean concepts are widely applied across various sectors, including the automotive industry, healthcare, software development, and the supply chain, demonstrating their flexibility and applicability. The lean philosophy guides organizations across multiple sectors by emphasizing the elimination of waste, continuous improvement, and the creation of value for customers as a comprehensive management approach. Lean methods are adapted for use outside of manufacturing, such as in healthcare and IT, to enhance efficiency and minimize waste across various processes. The concept of a lean enterprise extends lean thinking beyond the factory floor, integrating lean principles across all departments and strategic operations.

Lean’s core principles—focus on value, flow, pull, and perfection—remain consistent whether you’re managing a factory or a service team.

Final Thoughts: The True Meaning of Lean Manufacturing

The meaning of lean manufacturing lies in its holistic blend of philosophy and practice. The term “lean manufacturing” originated from the evolution of production systems, such as Just-In-Time (JIT) and the Toyota Production System (TPS), and has become significant due to its focus on maximizing value through process efficiency and continuous improvement. It’s a lean manufacturing methodology designed to:

- Banish waste

- Create value at speed

- Deliver quality

- Build a culture of continuous improvement

Lean manufacturing emphasizes waste reduction and the development of efficient processes as core outcomes, ensuring streamlined and sustainable workflows that benefit both organizations and their customers.

By embracing lean, you transform not only your manufacturing plants but also your strategy, supply chain, and relationships with customers and suppliers alike.

✅ Begin your lean journey: Explore the Lean Management Course and experience practice-first learning with the GET LEAN Simulation Game.