Spis treści

Methodology of 5S: A Comprehensive Guide to Workplace Transformation

Achieving operational excellence in today’s competitive business environment requires a structured and sustainable approach. Among the most effective frameworks for boosting workplace efficiency and safety is the 5S methodology. Initially developed in Japan, 5S originated in the manufacturing industry and emphasizes its role in improving efficiency and organization in workspaces. It has become a cornerstone of Lean Management and a globally recognized best practice for organizations striving for continuous improvement. A continuous improvement culture is integral to the 5S methodology, ensuring that all employees actively participate in refining processes and maintaining efficiency. In this guide, we will thoroughly explore the 5S methods, define the 5S methodology, and show how you can apply it to create lasting, positive change in your workplace.

Introduction to 5S

The 5S methodology is a fundamental principle of visual management and a key component of the Toyota Production System (TPS). It is a structured approach to workplace organization that aims to improve efficiency, eliminate waste, and promote the adoption of lean principles. The 5S methodology is based on five Japanese words: Sort, Set in Order, Shine, Standardize, and Sustain. These five steps create a clean, organized workspace free of unnecessary items and hazards. By implementing the 5S methodology, organizations can improve their overall workplace efficiency, reduce waste, and promote a culture of continuous improvement.

What Is the Methodology of 5S?

The 5S methodology is a systematic approach to workplace organization, cleanliness, and standardization to improve efficiency, reduce waste, and ensure safety. To effectively implement 5S, it is crucial to provide necessary resources at each stage, from cleaning utensils to visual aids, to facilitate successful workshops and maintain organizational efficiency. Forming a dedicated team that involves employees from various departments is essential for effective implementation. It derives its name from five Japanese words:

- Seiri (Sort): Remove unnecessary items from the workplace by identifying and marking them with red tags.

- Seiton (Set in Order): Organize necessary items for easy access.

- Seiso (Shine): Thoroughly clean the work environment. Establishing cleaning schedules is essential to maintaining cleanliness and order over time.

- Seiketsu (Standardize): Develop standards to maintain the first three steps.

- Shitsuke (Sustain): Foster a culture of discipline to uphold the standards.

By applying the 5S methodology, organizations create environments that are organized, efficient, and conducive to high performance.

Want to transform your workplace into a model of efficiency and safety? Enroll in our practical 5S training course here!

Define 5S Methodology: Breaking Down the Five Steps.

To fully define 5S methodology, it’s essential to understand the purpose behind each step:

Seiri (Sort)

- Use red tags during the sorting phase to identify and mark unnecessary items. This is crucial for eliminating unnecessary items.

- Focus only on what adds value to the workflow.

- Free up space and reduce distractions.

Seiton (Set in Order)

- Arrange tools, equipment, and materials logically.

- Ensure that everything has a designated place.

- Utilize visual management techniques to simplify locating items.

- Organizing necessary items helps reduce excess motion, making it easier to access and return items to their designated homes.

- Organizing necessary items contributes significantly to creating an efficient workplace, reducing operational variation, and enhancing production quality.

Seiso (Shine)

- Clean all work areas and equipment regularly. Regular cleaning and maintenance contribute to employee well-being by ensuring a safe and hygienic workplace.

- Spot and address any maintenance needs during cleaning.

- Create a sense of pride and ownership among employees.

Seiketsu (Standardize)

- Implement standardized work procedures to develop clear guidelines and schedules. Establishing cleaning schedules is crucial to standardizing practices and maintaining cleanliness and order over time.

- Use checklists and visual cues to maintain standards.

- Ensure that all areas operate consistently.

Shitsuke (Sustain)

- Build discipline and self-regulation among employees.

- Conduct regular training sessions and audits.

- Recognize and reward adherence to 5S standards.

- Emphasize the role of positive reinforcement in sustaining 5S standards by fostering a culture of organization and efficiency.

Understanding how to properly define the 5S methodology is crucial to successful implementation.

Why the Methodology of 5S Matters

The 5S methodology is not just about tidiness. It plays a strategic role in achieving key business goals and creating an efficient work environment:

- Efficiency: Streamlined processes and quick access to tools reduce downtime.

- Safety: Clean, organized spaces reduce workplace hazards.

- Quality: Standardization reduces errors and improves product quality.

- Morale: Employees feel more valued and motivated in a well-organized environment.

- Cost Reduction: Efficient use of space, materials, and time lowers operational costs.

- Alignment: Ensuring all team members are on the same page during 5S implementation fosters a unified approach and better results.

Companies that embed 5S into their culture achieve sustainable improvements across multiple performance metrics by eliminating waste and optimizing processes. Integrating 5S into the organization’s culture is essential for long-term success, ensuring continuous improvement and positive outcomes.

Discover how the 5S methodology can revolutionize your workplace by joining our comprehensive training program here!

Benefits of 5S

The 5S methodology offers numerous benefits to organizations that implement it. One of the most significant advantages is improved workplace efficiency. Employees can focus on value-added tasks by eliminating unnecessary items and organizing the workspace, thereby enhancing overall workplace efficiency. This structured approach streamlines operations and reduces waste, a core principle of lean manufacturing.

Moreover, the 5S methodology promotes a culture of continuous improvement. Employees are encouraged to identify areas for enhancement and implement changes, fostering an environment where ongoing improvement is the norm. This proactive mindset is integral to the Toyota Production System, where continuous improvement and efficiency are paramount.

A clean and organized workspace also positively impacts employee morale and well-being. Employees working in a tidy environment are more likely to feel valued and motivated, leading to increased job satisfaction and reduced turnover. The 5S methodology, therefore, not only boosts productivity but also contributes to a healthier, more engaged workforce.

In summary, the 5S methodology is a key component of lean manufacturing. It offers a structured approach to eliminating unnecessary items, improving workplace efficiency, and fostering a culture of continuous improvement. By creating an organized workspace, organizations can achieve significant improvements in performance and employee well-being.

Tools and Resources for 5S

Implementing the 5S methodology requires the right tools and resources. Teams implement the 5S system to create more efficient, safer workspaces. Some essential tools include red tags, shadow boards, visual controls, and signage. Red tags mark items not needed in the workspace, while shadow boards indicate the correct location for tools and equipment. Visual controls and signage help employees understand storage instructions and maintain a clean and organized workspace. Additionally, digital tools such as UTrakk software can support the 5S methodology by providing digitalized 5S audits and checklists.

How to Implement the Methodology of 5S

Step 1: Initial Assessment

- Conduct a 5S audit to evaluate the current state of the workplace. The initial implementation phase is crucial as it sets a strong foundation for new practices that can become habitual within the organization.

- Identify areas with clutter, inefficiencies, and safety concerns.

Step 2: Planning and Communication

- Develop an implementation plan.

- Communicate the goals and benefits of 5S to all employees. Strategies for encouraging buy-in at all levels of the organization include fostering transparency and active communication to ensure understanding and employee participation.

- Build a team to lead 5S efforts.

Step 3: Pilot Project and Visual Management

- Choose a small area or department to test the 5S methodology. Implementing 5S involves basic organization and creating an efficient and safe environment.

- Apply each of the five steps thoroughly.

- Identify and initiate improvement projects to eliminate waste. These projects are critical for fostering a culture of continuous improvement and can be integrated effectively with Six Sigma principles to enhance productivity and quality.

Step 4: Organization-wide Rollout

- Expand 5S practices to all areas based on pilot project learnings, ensuring the involvement of the entire organization.

- Customize approaches to suit different departments and workflows.

Step 5: Sustain and Improve

- Schedule regular audits and refresher training.

- Celebrate successes and recognize employee contributions.

- Continuously seek ways to refine and improve standards.

- Foster a continuous improvement culture to ensure all employees actively participate in refining processes and maintaining efficiency.

Leadership and 5S

Effective leadership is crucial for the successful implementation of the 5S methodology. Senior management must actively participate in 5S initiatives and provide resources to stakeholders. Team leaders are critical in guiding and motivating their teams during improvement. They must set an example and encourage their teams to follow the rules. Organizations can ensure that the 5S methodology is sustained over the long term by involving management and team leaders.

5S and Operational Excellence

The 5S methodology is a crucial element of operational excellence, providing a structured approach to workplace organization and efficiency. By implementing the 5S method, organizations can significantly reduce waste, improve productivity, and promote a culture of continuous improvement. The five Japanese words that comprise the 5S methodology—sort, Set in Order, Shine, Standardize, and sustain—offer a clear framework for organizations to follow in their pursuit of operational excellence.

Effective implementation of the 5S methodology requires the involvement of the entire organization, from senior management to team leaders and employees. This collective effort ensures that the principles of 5S are deeply ingrained in the organization’s culture. Organizations can create a visual workplace that promotes efficiency, reduces waste, and improves overall performance by working together.

Visual controls, such as shadow boards and floor marking tape, are vital in maintaining cleanliness and organization. These tools help to reduce the risk of equipment failure and improve employee safety by clearly indicating the correct location for tools and materials. Regular audits and ongoing improvement processes are essential to successfully implementing the 5S methodology and achieving operational excellence.

In conclusion, the 5S methodology is a structured approach that supports operational excellence by promoting workplace organization, reducing waste, and fostering a culture of continuous improvement. Companies can maintain cleanliness, enhance safety, and achieve significant performance improvements by involving the entire organization and utilizing visual controls.

Examples of 5S in Different Industries

Manufacturing

- Tool organization with shadow boards

- Clear labeling of storage areas

- Routine equipment cleaning and maintenance

- Effective organization of the shop floor to enhance efficiency and minimize waste

- Implementation of 5S to streamline production processes and maintain order. Maintaining 5S procedures on the manufacturing floor is crucial for eliminating waste and enhancing efficiency.

- 5S aligns with lean production principles to optimize productivity and reduce waste.

Healthcare

- Efficient storage and labeling of medical supplies

- Organized patient care areas

- Standardized procedures for cleanliness and hygiene

- Many organizations conduct peer audits to evaluate adherence to 5S principles and monitor the progress of their initiatives.

- Implementation of a visual factory to enhance workplace organization through indicators and charts, aligning with the 5S management approach

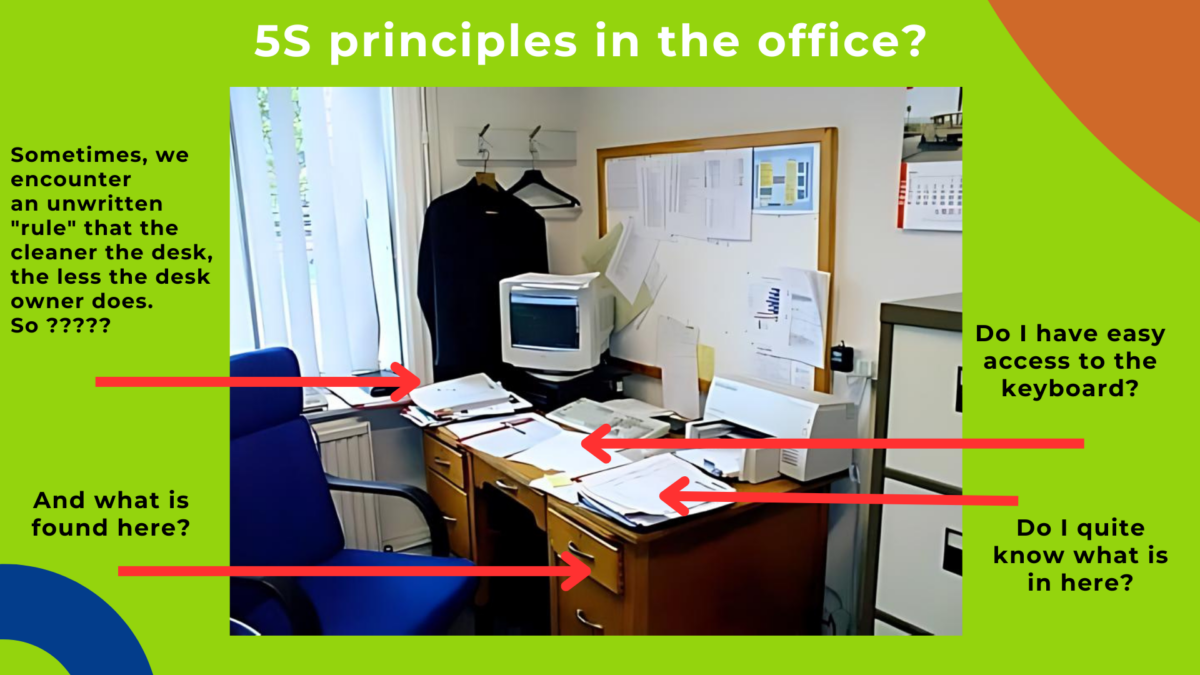

Offices

- Filing systems for documents

- Organized desk spaces

- Standard templates for reports and communications

- Visual workplace tools like labels, floor markings, and charts can be used to create a cleaner, more navigable workspace

5S helps create a productive workspace by eliminating clutter and distractions.

Retail

- Structured stockroom layouts

- Efficient product display arrangements

- Clean and accessible customer service areas

- Organized stockrooms to reduce excess inventory

Regardless of the industry, the 5S methodology adapts to support operational excellence.

Want to see how 5S can be tailored to your specific industry? Explore practical approaches in our expert-led course here!

Common Challenges in 5S Implementation and Eliminating Waste

Even with a clearly defined 5S methodology understanding, companies may face obstacles:

- Resistance to Change: Employees might view 5S as extra work.

- Lack of Consistency: Without standardization, early gains are lost.

- Poor Leadership Commitment: Without visible management support, initiatives falter.

5S promotes continuous improvement by fostering a culture of organization and efficiency.

Solutions include:

- Clear communication of 5S benefits

- Active involvement of employees at every stage

- Strong leadership endorsement and participation

- Visible support from the management team to reinforce the benefits and foster team ownership and engagement

Measuring the Success of 5S

Key performance indicators (KPIs) for evaluating 5S success include:

- Reduction in search time for tools and materials

- Decrease in workplace accidents

- Improvement in product or service quality

- Increase in employee engagement and satisfaction

- Improved quality through standardized work procedures, regular cleaning, and a more efficient workplace

Regular audits and employee feedback loops help sustain the methodology and drive continuous improvement.

Benefits of 5S Training in a Continuous Improvement Culture

Investing in professional training on the methodology of 5S ensures:

- Faster and more successful implementation

- Greater employee buy-in and understanding

- Long-term sustainability of 5S practices

- Development of internal 5S champions

- Significant improvements in efficiency, quality, and safety

The Toyota Motor Company developed the 5S methodology as part of the Toyota Production System.

Learn from real-world examples and proven methods by enrolling in our dedicated 5S training course here!

Conclusion: The Lasting Power of the Methodology of 5S

The 5S methodology is more than an organizational tool; it is a way of thinking that transforms workplaces into hubs of efficiency, safety, and continuous improvement. When you truly define the 5S methodology, you see it as a foundational system that supports broader operational excellence initiatives like Lean Manufacturing, Six Sigma, and Kaizen.

Whether starting your 5S journey or refining your current practices, a strong understanding of the methodology ensures that the principles of Sort, Set in Order, Shine, Standardize, and Sustain become deeply ingrained in your organizational culture. Lean thinking is crucial to sustaining the 5S methodology by fostering a culture of continuous improvement and promoting efficiency and waste elimination across diverse business environments.

Final Invitation

🎓 Rediscover the Power of 5S with a Practical, Proven Approach

Looking for a structured way to create a cleaner, safer, and more efficient workplace? This course delivers more than just theory — it gives you practical tools shaped by real-world experience.

Developed from over 25 years of implementing Lean and 5S systems in diverse industries, this training offers a step-by-step path to lasting operational improvement.

👉 The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization

What you’ll gain:

🎥 Self-paced learning – Access short, focused lessons anytime

♾️ Lifetime entry – Return to the material whenever needed

🧰 Practical downloads – Red tag templates, checklists, and audit tools ready for immediate use

📘 Cultural depth – Learn the original intent behind each “S” as practiced in Japanese industry

👉 Want to preview the experience?

If you’re ready to move from scattered efforts to a systematic approach, this course will guide you every step of the way.