About course

- Certified Lean Management video training

- 5.5 hours of practical content

- Lifetime access

- One-time payment

- Train your whole team

- Watch anytime, on any device

- Includes PDF tools and templates

- Certificate of completion

- VAT invoice included

- Created by Lean expert with 25+ years of experience

- Master core Lean principles and tools

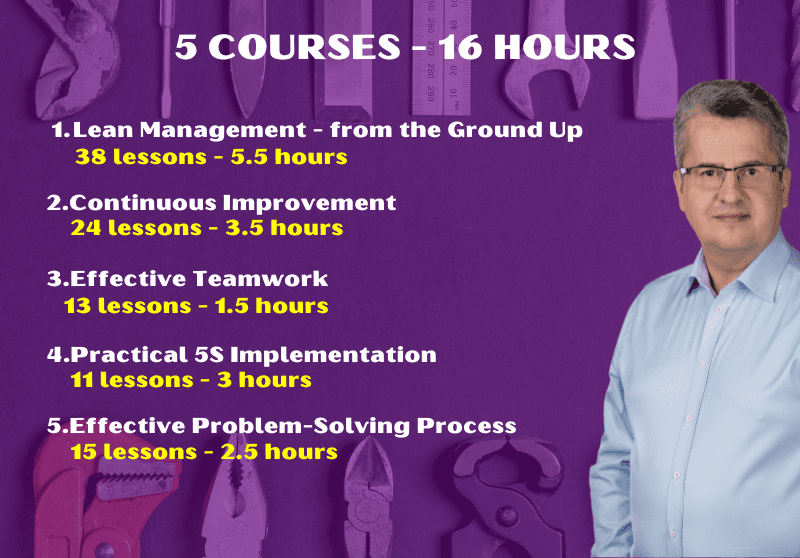

- One payment – get 5 courses at a special price

- Free with Get Lean game

About the course

This course stands out for its practical approach, developed by a specialist with 25 years of experience implementing Lean principles. It combines theoretical foundations with real-life examples and case studies, enabling participants to understand key concepts and effectively apply them in their daily work. The program covers identifying and eliminating waste, process optimization, and introducing a culture of continuous improvement within organizations. Additionally, the course offers numerous downloadable materials that support learning and allow for further deepening of acquired knowledge. With a step-by-step overview of Lean Management, participants can see the entire Lean implementation process clearly and understandably. Participation in the course provides skills highly valued in the job market.

For everyone who purchases the Get Lean game, enrollment in this course is free.

Why You Should Enroll in This Course:

- Gain highly sought-after skills in the job market

- Master Lean management step by step

- Learn powerful Lean tools: 5S, Kanban, Value Stream Mapping

- Boost efficiency in any professional role

- Access a wealth of additional learning materials

- Learn from an expert with 25 years of experience

- Pay once and enjoy lifetime access

- Share knowledge with your team

Sajhisomanath –

Lean Manufacturing course its very interesting understandable with great examples. so simple but deep insights. thank you

Shriram Bharathwaj (verified owner) –

Well-structured content and to the point. Clear and articulate. The speed of narration is perfect.

El Badaoui S. (verified owner) –

The Lean Manufacturing course was exceptional, offering a clear and practical approach to efficiency and waste reduction. The instructors provided valuable insights and real-world examples, making complex concepts easy to grasp. Interactive elements and practical applications ensured that I could immediately apply what I learned to my work environment. Overall, the course was highly informative and instrumental in enhancing my understanding of Lean principles. Highly recommended for anyone looking to improve their operational processes.

Mildred Acevedo (verified owner) –

Very informative course! I had fun taking notes as everything was explained very clearly. It reinforced my knowledge in lean manufacturing as I realized it matches well with how I normally prefer to work. Thank you

Amjad (verified owner) –

An Exceptional Course.

Sajimon V S (verified owner) –

its very interesting understandable with great examples. so simple but deep insights. thank you

Darnell G Wyatt (verified owner) –

Its Good Stuff, I picked this course over doing some research on others and was not disappointed. Clear and Concise!

Mbali Zungu –

EXCELLENT COURSE, WELL PUT,DELIVERED, STRUCTURED AND INFORMATIVE.

Ashutosh Yesugade –

Till now the course have explained me the difference between a traditional and lean approach which is quite interesting

Anup Chandran –

i like how you have compared different aspects of manufacturing using traditional and lean methods – Production Layout, Production Cycles, Quality etc.

Marcus Andrews –

It is easy to follow along.

Jayson –

The discussions on Lean leadership were particularly insightful and have already influenced my approach to management.

Dorota Jakowlew –

The Lean Manufacturing course on Udemy impressed me with its practical approach. It offers an in-depth introduction to the principles of Lean Manufacturing, focusing on real-world applications, making the content very useful and easy to implement. The instructor presents all the concepts and methods clearly, making it easy to understand and apply the principles of Lean Manufacturing in everyday work. I particularly appreciate the practical examples and exercises, which help consolidate the knowledge and see how the theories work in practice.

Vladislav Meijeris – Chief Imos Designer at Al.De.Mebel –

After 2 months of learning, I’ve just completed the LEAN course by Jan Sabat

It wasn’t just theory — I wrote more than 150 pages by hand, reflected on every topic, and got many new ideas on how to improve processes. This journey helped me look at work from a new perspective and inspired me to take action.

Here are a few things I really want to bring into our company:

👥 Involving the whole team in searching for wastes — because people on the shop floor see much more than we sometimes think.

📑 Standardization, guides, instructions, and trainings — the foundation for developing strong teams.

⚙️ TPM (Total Productive Maintenance) — to prevent problems instead of fixing them later, and to protect the company from expensive downtime.

For me, LEAN is not only about efficiency, but also about mindset: to see problems as opportunities for improvement.

💡 I’m curious — which LEAN principle do you find the most powerful in your daily work?

Shahinur Islam –

Yes it meet my expectation for became a lean master and production process learner.