Spis treści

Seiri: The First Step in 5S for an Efficient and Organized Workplace

In Lean Manufacturing and workplace organization, Seiri is the critical starting point for creating a clutter-free, safe, and highly efficient environment. As the first of the five pillars in the 5S methodology, Seiri focuses on sorting and removing unnecessary items from the workspace, laying the foundation for a systematic approach to workplace organization. The 5S methodology, including Seiri, was developed as part of broader efforts to improve workplace organization and efficiency. Early management theories, such as scientific management, influenced the development of Seiri and the 5S system. This article will guide you through what Seiri is, how it fits into the bigger picture of continuous improvement, and why mastering it can dramatically transform your operations. Authoritative resources on 5S and workplace organization, such as those published by Productivity Press, provide further reading.

For a deeper dive into practical Seiri implementation and the entire 5S system, check out this comprehensive course: The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization.

What Is Seiri?

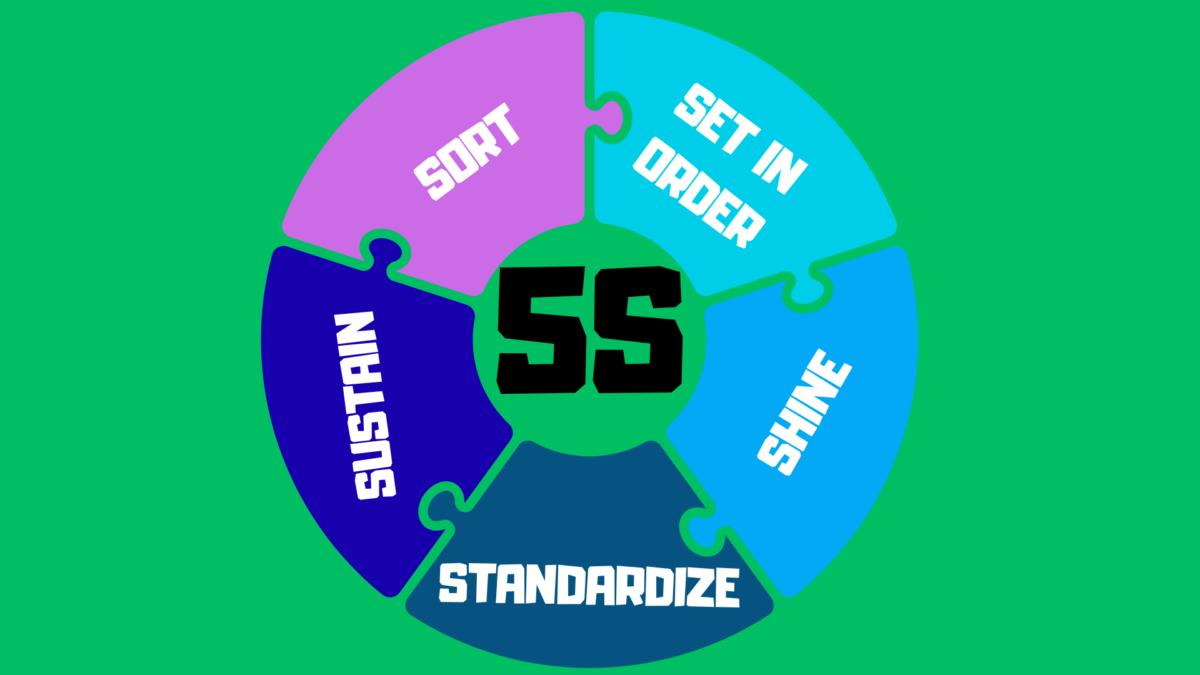

Seiri is a Japanese term that means “to sort.” It represents the first step in the 5S methodology, which includes Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). Originating from the Toyota Production System, Seiri emphasizes identifying necessary items in the workplace and removing what’s unnecessary. Seiri involves specific tasks that must be carried out to ensure effective sorting. By doing so, Seiri helps reduce waste, improve workplace efficiency, and enhance visual management.

In practice, Seiri is not just about tidying up. It’s a methodical process of evaluating tools, materials, and equipment, categorizing them as necessary, unnecessary, or uncertain, and then taking action to keep, discard, or reallocate them. Items are sorted into categories, and unneeded items are identified for removal. The Seiri process helps implement improvements by continuously reviewing and optimizing the workspace. This step is crucial in creating a visual workplace that enables quick access to essential items, boosting productivity and safety.

To explore practical tools for applying Seiri, including visual techniques like the red tag system—a tool used to support Seiri tasks—consider enrolling in the 5S Workplace Organization course for actionable strategies.

Why Seiri Matters for Continuous Improvement

Seiri’s role in continuous improvement cannot be overstated. Removing unneeded items directly supports lean management by making sure Seiri practices are implemented across the company to ensure lasting results:

- Reducing waste: Every extra item is a potential source of clutter, delay, or risk.

- Creating space: Freeing up workspace enables better workflow and optimizes productivity.

- Improving safety: A clean, organized workspace reduces hazards.

- Enhancing visual control: Clear, visual cues ensure that only necessary tools remain accessible.

Note: Standardized practices help maintain Seiri’s benefits by ensuring consistency and supporting ongoing improvement.

Without a solid Seiri foundation, the remaining 5S steps cannot function effectively. Experts recommend starting any 5S implementation with a focused Seiri audit. Seiri is most effective when it becomes part of the company’s culture and is implemented as a standardized process. Need guidance on getting started? Our practical course, which includes ready-to-use templates and red tag tools, teaches you how to implement 5S in your organization.

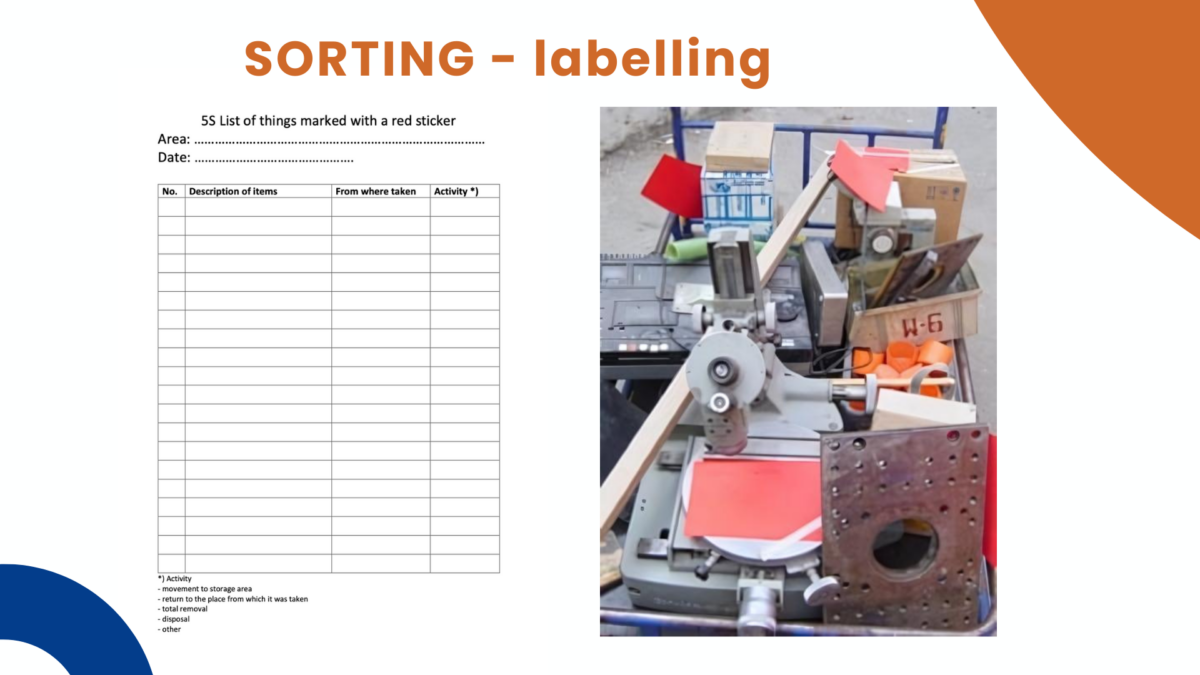

The Red Tag System: A Key Element of Seiri

One of the most potent tools for Seiri is the red tag system, a tool commonly used on the shop floor to support workplace organization. This approach helps teams systematically identify and handle unnecessary items:

- Red tags are placed on items of uncertain value.

- Items are moved to a quarantine area for evaluation.

- If an item remains unused for a set time, it is discarded, sold, or relocated.

This simple yet effective method is a cornerstone of the 5S system, helping organizations take decisive action in organizing the workspace.

Real-World Benefits of Seiri

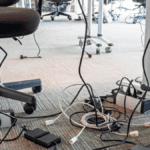

An example of a cluttered workspace before Seiri is applied can be seen in a factory where tools, materials, and paperwork are scattered across surfaces, making it difficult to find what is needed and slowing down processes.

Companies across industries—manufacturing, healthcare, logistics, and offices—apply Seiri to create tangible results:

- Manufacturing firms like Toyota use Seiri to transform cluttered workplaces into efficient environments. By removing broken tools and unneeded items, Seiri improves productivity and quality.

- In healthcare, decluttering storage areas can reduce waste, improve patient care, and speed up response times.

- In offices, Seiri helps clear work stations, enabling quick access to essential items and reducing time wasted searching for tools.

These success stories underscore the value of learning Seiri step by step through a structured course. If you’re ready to implement Seiri in your workplace, don’t miss our in-depth program: The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization.

Seiri and Team Engagement

Seiri is not a solo effort. It thrives on building participation across teams. Active worker involvement is essential, as their habits, self-discipline, and commitment are key to sustaining Seiri practices. Engaging employees in Seiri:

- Encourages ownership of the process.

- Strengthens self-discipline.

- Creates a culture of continuous improvement.

- Reduces resistance by giving employees a voice.

For managers and team leaders seeking to build strong, collaborative teams, the Teamwork and Leadership course complements Seiri training by offering strategies to foster engagement and leadership.

The Role of Self-Discipline in 5S

Self-discipline is a key element in the 5S methodology, serving as the backbone for sustaining a clean, organized, and efficient workplace. The fifth step of 5S, known as Shitsuke, focuses on developing and maintaining the habits that keep your work area free of unnecessary items and clutter. This step is crucial for continuous improvement, ensuring that the gains achieved through 5S implementation are not lost over time.

In the Toyota Production System and lean management context, self-discipline empowers employees to take ownership of their workstations, regularly evaluate their processes, and proactively remove waste. Organizations can maintain high workplace efficiency, quality, and productivity standards by fostering self-discipline. Employees become more engaged in keeping their tools, equipment, and materials organized, directly supporting visual management and control systems.

Practicing self-discipline means consistently following established procedures, maintaining equipment, and cleaning up after each task. It also involves developing routines that encourage everyone to identify and remove unnecessary items, ensuring that only what is needed remains in the workspace. This ongoing commitment to improvement helps prevent the gradual buildup of clutter and disorganization, which can undermine even the best 5S implementation.

Self-discipline transforms 5S from a one-time project into a lasting business improvement culture. When employees are committed to sustaining improvements and continuously optimizing their work areas, organizations can achieve higher productivity levels, reduce waste, and create a safer, more organized workplace. By making self-discipline a daily practice, companies lay the foundation for ongoing success in lean management and continuous improvement.

Challenges in Seiri Implementation

While Seiri offers many benefits, challenges such as employee resistance, lack of management support, and inconsistent follow-up can arise. To achieve long-term success, Seiri must be implemented effectively with careful planning and supported by ongoing maintenance to sustain organized, efficient work environments. The solution? Equip teams with proper training, like the 5S Workplace Organization course, to ensure everyone understands the “why” and “how” behind Seiri. Combine Seiri with robust problem-solving skills from the Effective Problem-Solving Process course for maximum impact.

Seiri in the Context of 5S and Lean

Seiri sets the stage for Seiton, Seiso, Seiketsu, and Shitsuke. By removing unnecessary items, Seiri lays the groundwork for standardized practices in the following 5S steps, ensuring workspaces are set up for consistency and efficiency. Together, these steps help organize the workplace, create a visual factory, and establish a system for sustained workplace organization and continuous improvement. Mastering Seiri means mastering the first step of the 5S system—and that starts with rigorously applying its principles.

Download the resources and templates from our 5S Workplace Organization course for a practical guide to implementing all five steps. Access it here: The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization.

Final Thoughts: Start Your 5S Journey Today

Mastering Seiri is your first step towards a more productive, safe, and efficient workplace. To ensure success, you need a solid foundation in 5S principles, practical tools such as red tags, and a transparent implementation process. Maintaining a clean, organized workspace is essential to sustaining the benefits of Seiri and 5S. The 5S Workplace Organization course provides all this and more, designed to help you apply 5S practically across different industries. With over 25 years of hands-on experience in Lean Manufacturing and 5S, I’ve distilled the essential lessons, tools, and templates into a comprehensive learning resource.

🎓 Ready to transform your workplace with 5S? Join today’s course: The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization. You can even preview a sample lesson to see the depth and practicality of this training.

For an interactive experience, don’t miss the GET LEAN Simulation Game, designed to bring Lean principles to life in a dynamic learning environment.