What is Lean Production? Understanding the Core of Modern Manufacturing Efficiency

In today’s competitive manufacturing landscape, companies must produce high-quality goods, meet fluctuating customer demand, and minimize waste. This is where lean production comes into play. But what is lean production? At its core, lean production systematically eliminates waste within a manufacturing system while improving productivity and quality. Lean principles were first found in the early 20th century, with key figures like Frederick Taylor and later Shigeo Shingo and Taiichi Ohno shaping their foundation, particularly through the development of the Toyota Production System (TPS). Originating from the Toyota Production System (TPS), lean production emphasizes value creation for the customer and continuous improvement throughout the production process, making it especially important for modern manufacturing success.

Over the years, lean production has evolved significantly, with important milestones such as the adoption of just-in-time manufacturing in the 1970s and the global spread of lean practices in the following decades.

Origins and Evolution of Lean Production

Lean production is rooted in Japan’s post-World War II recovery era, where low demand for goods pushed manufacturers to minimize waste and avoid overproduction. Toyota, in particular, revolutionized the manufacturing industry by developing a new approach that focused on eliminating waste (“muda”), optimizing workflows, and increasing efficiency. This approach, later termed the Toyota Production System (TPS), became the foundation for what is now known globally as lean manufacturing or lean production. The findings of key figures like Shigeo Shingo and Taiichi Ohno were instrumental in shaping lean production, as their analyses and improvements refined the system’s core principles.

The lean philosophy gradually spread globally, impacting industries far beyond automotive manufacturing. Some critics fought against or challenged lean practices in the early years, questioning their impact and effectiveness. As lean production was adopted in new industries, its methods and principles changed to fit different operational needs and environments.

Today, lean production principles are applied across aerospace, healthcare, software development, and logistics sectors. Critics have raised concerns about lean’s impact on employees and management culture, highlighting potential drawbacks alongside its benefits.

Whether you’re just starting or refining your lean approach, the Lean Management course delivers comprehensive, hands-on guidance.

Core Principles of Lean Production

The success of lean production lies in its foundational principles. These include:

- Identify Value – Value is determined from the customer’s perspective, focusing on what the customer considers valuable.

- Map the Value Stream – Analyze all steps in the production process, evaluate each step for value and waste, and remove steps that do not add value.

- Create Flow – Ensure that production steps flow smoothly without interruptions or delays.

- Establish Pull – Produce items based on actual customer demand, not forecasts.

- Seek Perfection – Continuously improve processes to strive for perfection.

These lean principles form the backbone of lean production systems and guide companies in building more responsive, efficient, and customer-focused operations. Lean production’s scope is broad, addressing the entire value stream, unlike other manufacturing methods that may have a narrower focus, such as just-in-time, which emphasizes inventory management and cost reduction.

The Lean Production Process in Action

A typical lean production process begins by understanding customer requirements and aligning all production activities accordingly. Manufacturers work to optimize the process by reducing unnecessary steps, streamlining workflows, analyzing individual parts for improvement, and implementing lean tools such as value stream mapping, Kanban systems, and 5S methodology.

Each process phase is evaluated for waste–overproduction, excess inventory, idle equipment, or over-processing. Lean production is a continuous process that requires regular change and adaptation to sustain improvements. By eliminating waste, companies can improve operational efficiency by maintaining consistent output, lowering costs, and delivering products faster without compromising quality. Teams are encouraged to find new ways to eliminate waste and improve efficiency.

Key Techniques and Tools in Lean Production: Kaizen

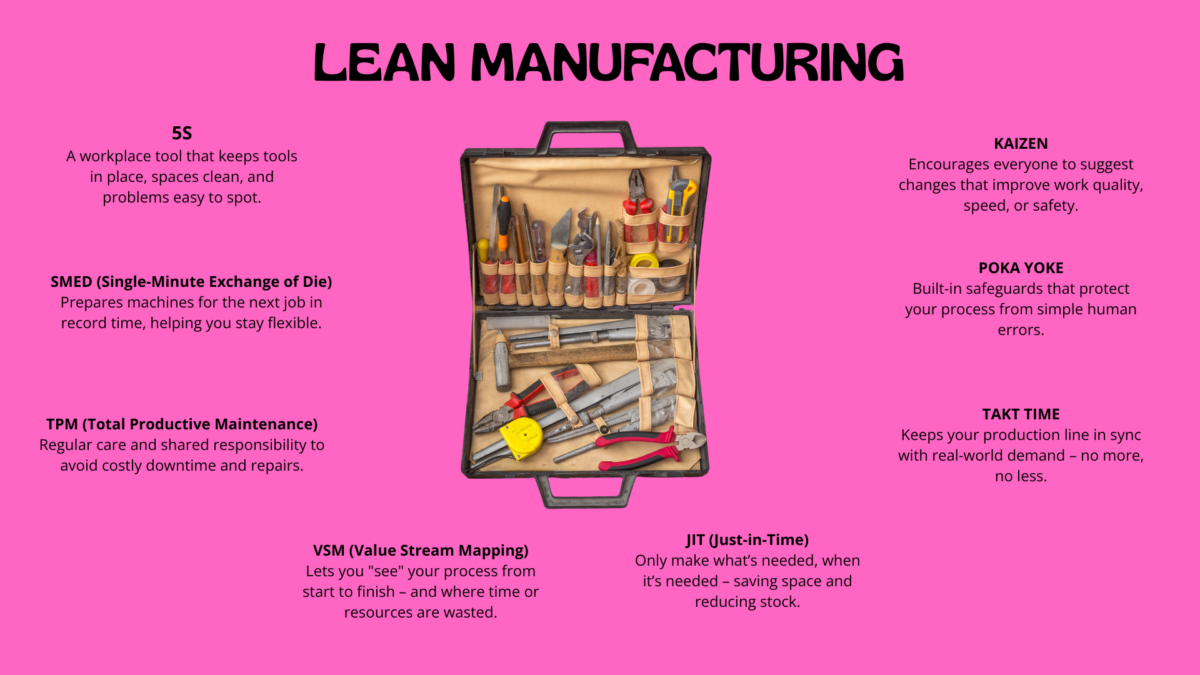

To implement lean production effectively, several tools and techniques are employed:

- Just-in-Time (JIT): Aligning raw material orders from suppliers directly with production schedules.

- Kanban: A visual workflow management system to control inventory and production.

- Poka-Yoke: Error-proofing mechanisms to prevent defects.

- Total Productive Maintenance (TPM): Ensures machinery is always in optimal working condition to prevent downtime and reduce malfunctions.

- 5S: Workplace organization method that improves efficiency and safety.

- Value Stream Mapping: A Visual representation of all steps and components to identify and eliminate waste.

- Production Leveling (Heijunka): Technique to smooth out and balance production processes, reducing fluctuations, inventory, and lead times while improving resource utilization.

These tools help reduce the production cycle, ensure quality control, and promote continuous improvement within the manufacturing process. Six Sigma can complement lean production by reducing defects and improving data-driven quality.

To unlock the full potential of lean methodologies, consider enrolling in the Lean Management course, packed with actionable strategies.

Just-in-Time Manufacturing: The Heartbeat of Lean

Just-in-time (JIT) manufacturing is a cornerstone of the lean production system, revolutionizing how the manufacturing industry approaches efficiency and waste reduction. Developed by the Toyota Motor Corporation in the 1950s, JIT focuses on producing and delivering products precisely when they are needed—no sooner, no later. This approach minimizes inventory levels, streamlines workflows, and ensures that resources are allocated only where they add value.

At the heart of JIT is the mechanism of continuous improvement, or Kaizen, which encourages operators and teams to seek ways to eliminate waste and enhance productivity constantly. By producing in small batches and responding in real time to customer demand, manufacturers can avoid the pitfalls of overproduction and excess inventory—two of the most significant wastes in traditional mass production.

JIT manufacturing not only improves operating performance but also enables businesses to stay competitive in a rapidly changing market. As Henry Towne, a pioneer in scientific management, emphasized, strategies like JIT are key for companies aiming to achieve high efficiency and adaptability. The result is a leaner, more responsive production process that delivers high-quality products with less time and fewer resources while fostering a culture of ongoing improvement and innovation within the industry.

Technology in Lean Production: Driving Modern Efficiency

In today’s fast-paced manufacturing environment, technology is a powerful driver of lean production, enabling companies to streamline workflows, reduce waste, and improve efficiency at every level. Integrating automation, robotics, and real-time data analytics allows manufacturers to identify inefficiencies and defects as they occur, making it possible to implement corrective actions immediately and prevent additional work or rework.

Experts like Jones and Womack have highlighted that leveraging technology is essential for achieving the full potential of the lean approach. Real-time data provides valuable insights into production workflows, helping businesses make informed decisions that lead to measurable improvements in productivity and quality. For example, advanced analytics can pinpoint bottlenecks. At the same time, automation can assist in developing a build-to-order system that aligns production schedules directly with customer demand, further reducing waste and inventory.

Moreover, technology fuels innovation by enabling manufacturers to develop new products and services, adapt to market changes, and maintain a competitive edge. However, successful implementation requires careful planning to ensure new systems do not introduce unnecessary complexity or additional work. When executed well, technology becomes a key component of the lean production system, supporting continuous improvement, waste reduction, and higher operating performance across the manufacturing industry.

Measuring Success in Lean Production: Metrics and KPIs

Evaluating the effectiveness of lean production initiatives is crucial for sustaining improvement and achieving long-term results. Success in lean is measured through various metrics and key performance indicators (KPIs) that clearly show progress and highlight opportunities for further enhancement.

Core metrics include lead time, inventory levels, productivity rates, and quality indicators—all of which reflect the impact of lean practices on the production process. Value stream mapping is a particularly valuable tool, enabling manufacturers to visualize workflows, identify waste, and target specific areas for improvement. Additional metrics such as cycle time, throughput, and overall equipment effectiveness offer more profound insights into operational performance.

Financial metrics, including cost reduction, revenue growth, and return on investment, help businesses assess the tangible benefits of lean implementation. At the same time, tracking employee engagement, customer satisfaction, and supplier performance ensures that improvements are felt across the entire value chain.

According to the president of Toyota Motor Corporation and other industry experts, consistently using metrics and KPIs is key to fostering a culture of continuous improvement. By regularly evaluating these indicators, manufacturers can drive ongoing waste reduction, boost productivity, and ensure that their lean initiatives deliver real, measurable results at every level of the organization.

The Lean Management course provides everything needed to understand and apply lean practices.

Benefits of Lean Production

Organizations that adopt lean production enjoy a range of benefits, including:

- Reduced operational costs and waste

- Improved customer satisfaction due to faster and more reliable delivery

- Enhanced productivity and manufacturing efficiency

- Greater employee engagement through participation in process improvement

- Better inventory management and use of raw materials

- Improved resource allocation, ensuring the right resources are assigned to optimize workflows and prevent overburdening workers

Lean production also enables organizations to redirect savings and spend on new initiatives, such as creating additional production lines or investing in competitive advantages.

Moreover, lean production helps businesses become more agile and responsive to supply chain and market demand changes, providing increased flexibility in adapting to production volume, delivery deadlines, and customer needs.

Lean production helps mitigate risks associated with operational challenges by minimizing inefficiency and waste. Additionally, lean principles contribute to a safer, more organized work environment, enhancing employee satisfaction and operational effectiveness.

Lean Production Beyond the Manufacturing Industry

Although traditionally associated with the manufacturing industry, lean production principles are now widely applied in sectors like:

- Healthcare – Streamlining patient care workflows

- Software Development – Using Agile and DevOps methodologies inspired by lean

- Logistics – Enhancing supply chain visibility and reducing transit waste

- Service Industries – Improving customer-facing processes and responsiveness

Producers in various industries have adopted lean principles to reduce waste, improve efficiency, and align with demand-driven production.

This cross-industry adoption demonstrates the lean production system’s adaptability and scalability. Many organizations in non-manufacturing sectors have received positive feedback and measurable results from implementing lean practices.

Implementing Lean Production Successfully

To implement lean production effectively, organizations should:

- Begin with a clear understanding of customer value.

- Train employees in lean tools and lean thinking.

- Involve cross-functional teams in identifying and eliminating waste.

- Involve people at all levels to encourage engagement and gather valuable insights for continuous improvement.

- Use performance metrics to track progress and drive improvements.

- Commit to a culture of continuous improvement and employee empowerment.

A well-trained workforce is essential for successful lean implementation, as it ensures employees are skilled and adaptable to changing processes. Lean production relies on effective communication and teamwork to achieve demand-driven results efficiently.

Leadership commitment and proper training are crucial to overcoming functional barriers and successfully implementing lean practices.

Learn More and Advance Your Lean Journey

A structured lean training program is essential for professionals and organizations eager to adopt lean methodologies and transform operations. Access to up-to-date information is crucial for advancing lean, enabling better decision-making and continuous improvement. Whether you’re new to lean or looking to deepen your expertise, consider enrolling in:

- Lean Management Course

- Effective Problem-Solving Course

- 5S Workplace Organization Course

- Continuous Improvement Course

- Teamwork and Leadership Course

Each course is designed to provide practical, hands-on knowledge for real-world lean implementation.

Conclusion

So, what is lean production? It’s more than a manufacturing method—it’s a philosophy that drives organizations toward greater efficiency, quality, and customer value. By applying lean principles and eliminating waste, businesses can streamline their production process, respond quickly to market changes, and sustain long-term operational excellence. The combined application of the lean tenets ensures that all crucial elements work together seamlessly, supporting sustained operational excellence.

Ready to make lean production a reality in your business? Start your journey today with Sabat Consulting’s expert-led courses and practical tools tailored to the needs of modern organizations.