Spis treści

Lean manufacturing has revolutionized how companies approach efficiency, value, and waste. At the heart of the lean philosophy is the goal to create more value for the customer with fewer resources by eliminating waste in all its forms. In lean manufacturing, waste manifests in various forms, including excess inventory, defects, and unnecessary motion, all of which can hinder operational efficiency. Understanding the wastes of lean is a crucial step in implementing lean principles effectively in any production process. The concept of waste in lean originated with the ‘seven wastes’ identified in the Toyota Production System, which later evolved into the ‘eight wastes’ recognized today as key areas to address for improved efficiency and reduced costs.

Introduction to Lean Manufacturing

Lean manufacturing is a systematic approach to optimizing the production process by eliminating waste and maximizing value for the customer. Originating from the Toyota Production System, lean principles have revolutionized manufacturing facilities worldwide, including those in the Western world, by focusing on streamlining processes and eliminating unnecessary steps. At its core, lean manufacturing seeks to identify and remove non-value-adding activities, whether they involve excessive motion, inventory waste, or over-processing. By continuously improving work processes and engaging employees at all levels, organizations can achieve more efficient processes, reduce costs, and deliver higher-quality products to the end customer. Lean thinking is now widely recognized as a foundation for operational efficiency and sustainable growth across various industries, extending beyond traditional manufacturing.

What Is Waste in Lean Manufacturing?

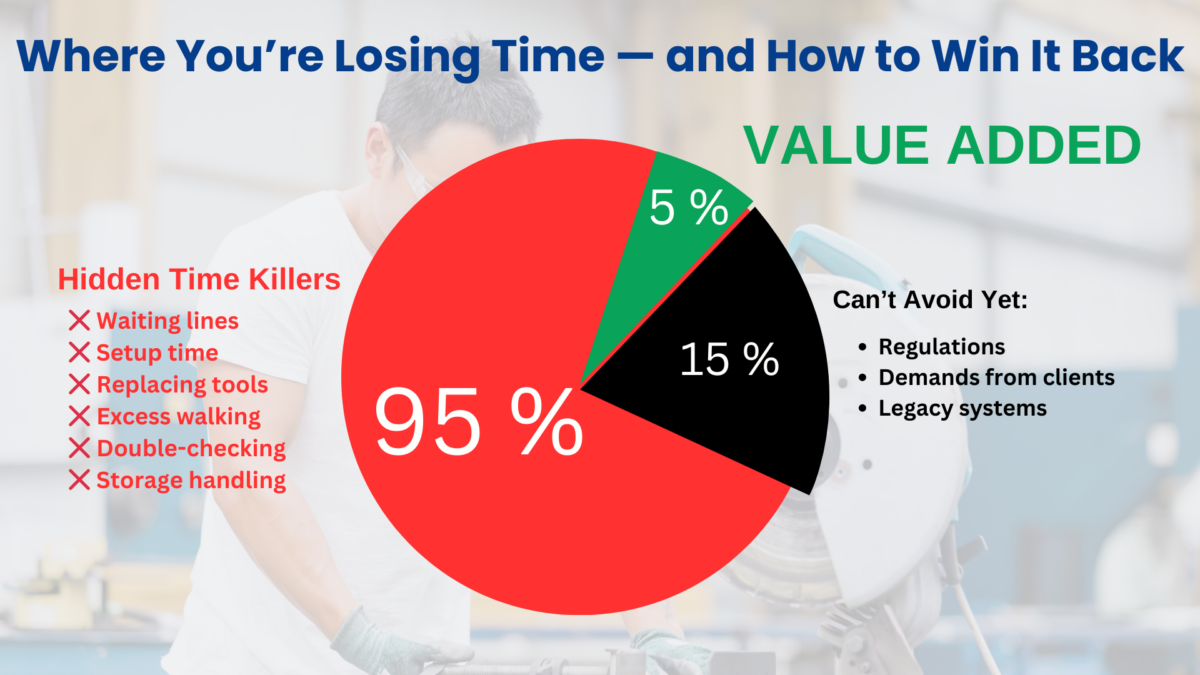

In the context of lean manufacturing, waste is any activity or process that consumes resources but does not add value to the end customer. In lean management, these non-value-adding activities are referred to as ‘lean waste,’ which are identified and targeted for removal to improve efficiency and profitability. The Toyota Production System was one of the first frameworks to categorize waste systematically. Lean management is the methodology that guides organizations in identifying and eliminating waste throughout their operations. These wastes, now commonly referred to as the eight wastes of lean, are seen as barriers to efficiency, profitability, and customer satisfaction.

The goal is to address waste by not only eliminating it but also by streamlining processes and fostering a culture of continuous improvement. Below, we explore each of the eight types of waste in detail, including their impact on the manufacturing process and practical strategies to combat them.

The 8 Wastes of Lean Manufacturing

1. Transportation Waste

This refers to the unnecessary movement of materials, products, or tools between processes. In many cases, unnecessary transportation increases the risk of damage, causes delays, and contributes to higher costs.

Examples:

- Moving parts between distant workstations

- Excessive material handling

- Long supply routes within a manufacturing facility

How to Reduce It:

- Optimize production line layouts

- Use value stream mapping to visualize and minimize flow distances

- Implement pull systems to limit over-transportation

- Review and optimize process steps to reduce unnecessary transportation

2. Inventory Waste

Excess inventory, whether in the form of raw materials, work-in-progress, or finished goods, ties up capital and can lead to product obsolescence. It also requires extra storage space and handling.

How to Address It:

- Reduce batch sizes

- Align inventory levels with actual customer demand

- Practice just-in-time inventory management

3. Motion Waste

Also known as unnecessary motion or excessive movement, this waste refers to any movement by workers or machines that doesn’t add value.

Examples:

- Reaching for tools located far away

- Excessive walking between work processes

- Searching for materials or documents

Solutions:

- Design ergonomic workstations

- Conduct a waste walk to observe wasted motion

- Implement 5S to organize tools and materials

4. Waiting Waste

Waiting waste happens when workers, machines, or materials are idle due to unbalanced workloads, equipment downtime, or poor scheduling.

Results in:

- Idle equipment and labor

- Delays in the production process

- Increased cycle time

Fixes:

- Balance workloads

- Implement preventive maintenance

- Use takt time planning

- Implement continuous flow to minimize waiting and ensure a steady production process

5. Overproduction

Overproducing means making more than what is needed or making it too early. This often leads to excess inventory and higher storage costs.

Prevent Overproduction By:

- Using pull systems instead of push

- Producing based on actual customer demand

- Monitoring production levels with KPIs

6. Overprocessing

This waste involves performing more work or using more materials than necessary. It often stems from poor planning, excessive quality checks, or using equipment that is too complex for the task at hand. Extra processing refers to unnecessary or redundant steps within a process that do not add value and only increase waste. Overengineering occurs when more features or complexity are added than necessary, resulting in inefficiency and unnecessary complexity.

Avoid Overprocessing By:

- Identifying and removing unnecessary steps

- Standardizing work processes

- Training staff on proper procedures

7. Defects

Defects are a direct drain on resources and a significant cause of waste. They require rework, additional inspections, or scrapping of materials.

Causes Include:

- Inadequate quality control

- Poor communication

- Lack of standard procedures

Prevent Defects With:

- Root cause analysis

- Investing in employee training

- Creating error-proofing systems (Poka Yoke)

8. Non-Utilized Talent

This refers to the failure to use people’s skills, talents, and ideas. Engaging employees in continuous improvement initiatives can uncover hidden opportunities and drive cultural change.

Enhance Utilization By:

- Encouraging employee feedback

- Involving employees in efforts to improve processes and operational efficiency

- Cross-training for multi-skilled teams

- Promoting lean thinking throughout the entire organization

How Lean Principles Help Eliminate Waste

The lean methodology uses a comprehensive approach to eliminate waste through practical tools and cultural shifts. Reducing waste is a central principle of lean manufacturing, leading to improved efficiency throughout the production process. Key lean tenets include:

- Define value from the end customer’s perspective.

- Identify the value stream for each product.

- Make the process flow smoothly.

- Establish a pull system.

- Strive for perfection through continuous improvement.

Continuous Improvement: The Heart of Lean

Continuous improvement, also known as kaizen, is the driving force behind lean manufacturing. It involves a relentless pursuit of better ways to perform work, reduce waste, and optimize resources throughout the production process. Rather than settling for the status quo, lean practitioners encourage teams to regularly review work processes, identify wastes, and implement small, incremental changes that add up to significant improvements over time. Engaging employees in problem solving and empowering them to suggest and test new ideas fosters a culture where everyone is responsible for eliminating waste and enhancing efficiency. This ongoing commitment to improvement ensures that lean manufacturing remains dynamic, adaptable, and directly related to long-term success.

Practical Strategies for Waste Reduction

1. Value Stream Mapping

One of the most powerful tools in identifying and eliminating waste, value stream mapping helps visualize every step in the production process.

2. 5S Implementation

This workplace organization method ensures tools and materials are always in their proper place, reducing motion waste and increasing efficiency.

3. Lean Training Programs

Many lean practitioners rely on structured training to instill lean thinking. These programs focus on problem solving, waste identification, and practical application.

Simulation Games: Bringing Lean to Life

A particularly effective way to teach waste elimination is through simulation games, such as GET LEAN. These hands-on experiences demonstrate how waste occurs in real-time, enabling participants to test strategies for improvement.

Games help participants:

- Understand the eight wastes of lean

- Identify non-value-adding steps

- Practice streamlining processes

The GET LEAN Simulation Game is also bundled with professional training courses designed to support companies in advancing their lean journey.

Benefits of Lean Manufacturing

Adopting lean manufacturing yields a wide range of benefits that span the entire production process. By systematically eliminating waste—such as transportation, waiting, and over-processing waste—organizations can significantly reduce costs and improve operational efficiency. Lean production leads to shorter cycle times, lower inventory levels, and faster response to customer demand, all of which contribute to higher customer satisfaction. Additionally, lean principles help improve product quality by minimizing defects and unnecessary work, while also optimizing the use of raw materials and additional resources. The result is a more agile, competitive, and resilient manufacturing facility that consistently delivers more value to the end customer.

Common Challenges in Lean Implementation

While the advantages of lean manufacturing are clear, many organizations encounter challenges when implementing lean principles. Resistance to change is common, particularly when employees are accustomed to traditional work processes or when leadership support is lacking. Insufficient training can lead to misunderstandings about lean concepts, resulting in poor planning or ineffective waste reduction efforts. Poor layouts and excessive reporting can create additional costs and hinder the flow of materials and information. To overcome these obstacles, it’s essential to invest in comprehensive lean training, foster open communication, and involve employees at every stage of the lean journey. Addressing these challenges head-on helps ensure that lean initiatives deliver lasting results.

Best Practices for Sustaining Lean Success

Sustaining the gains achieved through lean manufacturing requires ongoing commitment and strategic action. Leadership must champion lean thinking and allocate resources for continuous improvement activities, such as regular waste walks and process reviews, to drive sustainable improvements. Ongoing training and development keep employees engaged and equipped to identify wastes and suggest improvements. Establishing clear metrics and monitoring progress helps organizations stay focused on their goals and quickly address any setbacks that may arise. Embedding lean principles into the organizational culture—through recognition, cross-functional collaboration, and a focus on customer value—ensures that efficient processes and high standards become the norm. By following these best practices, companies can maintain momentum and continue to maximize efficiency in their production processes.

Why Addressing Waste Matters

Ignoring waste in your manufacturing process can result in:

- Higher costs

- Lower product quality

- Decreased customer satisfaction

- Wasted time

Conversely, addressing waste leads to:

- Improved operational efficiency

- Faster production processes

- Better alignment with customer value

Final Thoughts: Build a Culture of Lean

Understanding and eliminating waste in lean manufacturing is not a one-time event—it’s an ongoing mindset. From transportation waste to non-utilized talent, each form of waste drains your resources and distracts from delivering value.

By applying lean principles, engaging in targeted lean manufacturing training, and using interactive tools like the GET LEAN game, your organization can truly transform its production processes into models of efficiency, quality, and customer-focused excellence.